How to lubricate timing rollers

Depending on the car model, one or two tension rollers are installed to provide the necessary tension on the timing belt. The part is a pulley mounted on a closed ball bearing. When the engine is turned on, the roller rotates under the action of the rotating belt.

Timing drive device 1 - crankshaft toothed pulley; 2 — timing belt; 3 - tension roller; 4 - camshaft toothed pulley; 5 — toothed pulley of the coolant pump.

Lubricants used for heavily loaded bearings are suitable for the unit in question. The roller can heat up to temperatures above 80 degrees, so the chosen product must withstand high heat. High-temperature greases are recommended, which are made from petroleum products thickened with various soaps.

Tensioner rollers and Castrol lubricant

Lithium greases

Manufacturers use Litol-24 as a standard; they also lubricate bearings at the VAZ plant. But this product dries out quickly and has to be replaced. Therefore, it is better to replace this lubricant with an analogue, which is also made on a lithium basis, but has improved properties. Its operating temperature range should not differ from Litol-24: from -40 to +120° C. However, already at -30° C this lubricant begins to lose its properties. In colder conditions, it can only work due to the heated insides of the car, which level out the temperature difference. The shelf life of the lubricant is from 5 years. However, it is usually much larger.

Litol-24 is a standard, but not the best lubricant for timing rollers

Often, car enthusiasts purchase Ciatim 221 or Ciatim 201 with a lithium complex. These brands are also used by most automakers for processing parts. Cyatim 221 is made from more expensive components and can withstand high temperatures up to +150 degrees. In cold conditions, it can be used at temperatures from -60° C. This lubricant has a longer shelf life - up to 40 years.

Attention!

Cyatim 221 has a calcium thickener, so it cannot be mixed with lubricants made with lithium thickeners.

Cyatim 221 is a more durable and heat-resistant analogue of Litol-24

Cyatim 201 was developed in the USSR and is considered obsolete, but it will cost 4 times less. The maximum temperature that the product can withstand is only 90° C. This product retains its original properties even at -60 degrees, therefore it is often used in the regions of the Far North. When stored, the substance does not deteriorate for up to 4 years. Then, due to low colloidal stability, liquid oil begins to separate from the lubricant.

Tsiatim 201 is an outdated but cheap analogue of Tsiatim 221. Suitable for northern latitudes, as it does not freeze even at -60° C

Recommended imported analogues have class EP2. Car enthusiasts often use Suprema EP2 universal lubricant, suitable for all types of heavily loaded bearings. It contains additives that reduce wear and reduce stress on metal parts. It is resistant to water washout, has good adhesion, prevents the formation of rust, and costs only a little more than Litol. Operating temperature range: -35°C to 160°C, so the lubricant may not be suitable for very cold climates.

Suprema EP2 is an excellent foreign lubricant at a price comparable to the price of Litol-24.

Among the domestic analogues of Litol-24, it is worth highlighting the high-temperature lubricant MC 1510 Blue, designed for operation under high loads. Its dropping point is higher than that of most (even foreign) products - 350 degrees. The lubricant composition can be used in a temperature range from -40 to +180 degrees.

Domestic lubricant MS 1510 Blue

Xado restorative lubricant contains revitalizant. After application to the surface, a metal-ceramic coating is formed, due to which the original geometry of the parts is partially restored. It is recommended for repairing bearings; it is often purchased by drivers when problems are detected in the operation of the rollers. The manufacturer produces many types of lubricants that differ in purpose, characteristics, cost, and temperature ranges; on average, their operating range is from -20° C to +130-150° C.

Xado Reconditioning Lubricant

Gazpromneft also produces products in this range, for example, G-Energy LX EP 2. Thanks to a set of additives, it has extreme pressure properties and is resistant to oxidation. Operating temperature range - from -30 to + 160 degrees.

G-Energy LX EP 2 grease

A brief comparative description of the presented lubricants can be found in the table below.

| Name | Temperature range, °C | Dropping point, °C | Thickener type (soap) | Base oil |

| Litol-24 | -40 to +120 | +180 | Lithium | Mineral |

| Ciatim 221 | -60 to +150 | +200 | Calcium | Silicone |

| Ciatim 201 | from -60 to +90 | +175 | Lithium | Oil |

| Suprema EP2 | from -35 to +160 | +260 | Lithium | Mineral |

| MS 1510 Blue | from -40 to +180 | +350 | Lithium | Mineral |

| Xado restorative | up to +130-150 | +190 | Lithium | Mineral |

| G-Energy LX EP 2 | -30 to +120 | +250 | Lithium | Mineral |

Manufacturers typically indicate whether the product is suitable for mixing with other lithium-based products. For example, you can mix Shell Retinax EP 2 with domestic MS 1000. In this case, the determining parameter is the temperature range. If you take a non-high-temperature composition, it will melt and leak during operation.

CV joint grease-4

Lubricants of this series are produced by thickening with lithium soap. But they work better at medium and elevated temperatures than Litol-24. After a short overheating, the composition retains its original shape and can work without replacement. Typically, motorists choose CV joint-4, which was originally designed to lubricate constant velocity joints. Its temperature range is no different from Litol-24, that is, it can withstand from -40 to +150 degrees. Properties are improved due to molybdenum disulfide, which acts as an anti-wear additive.

CV joint grease-4

Now different brands produce products under the name CV joint-4. Therefore, the quality of the composition and type of additives depends on the chosen company. Usually on sale there is a 4M CV joint, for example, from the company Rusma. The components of the product do not react with plastic and non-ferrous metals. The lubricant works well even in frosts down to -50º C, the only drawback is that it loses its properties when exposed to water.

Attention!

If the car is used for travel in a region with a cold climate, and the roller creaks in frosty weather, then it is better not to use CV joint-4. Litol-24 contains similar components and is more suitable for the regions of the Far North. But mixing it with products from the CV joint family is not recommended.

Synthetic lubricants

Products from this category are protected from being washed out by water and do not harden before the specified period. This allows you to avoid re-lubrication throughout the entire service life of the unit. For the timing roller, high-temperature Total ALTIS SH 2, made on the basis of synthetic ester and polyurea amplifiers, is suitable. The service life of this product is twice as long as that of those made from polyurethane. Due to increased adhesion, the composition is not washed out even with frequent contact with water. The temperature range of the lubricant is from -40 to 180 ° C.

Total ALTIS SH 2 grease

The low-temperature lubricant Total Ceran XS 80 with increased protection against scuffing and premature wear can replace the product described above. It consists of a synthetic base oil with the addition of a thickener - calcium sulfonate. The maximum temperature of use is +150 degrees, the minimum - up to - 55 C. The product is resistant to oxidation and has anti-corrosion properties.

Total Ceran XS 80 grease

A few words about the importance of correct tension

Many motorists know that improper functioning of the timing belt can cause very serious engine damage. This is due to the principles of operation of the mechanism, which boil down to the timely and high-quality opening/closing of the engine valves. This approach not only allows you to adjust the valve timing of the internal combustion engine, but also differentiates between sensitive valves and constantly knocking pistons.

If the timing belt begins to work incorrectly, the gas distribution order is disrupted, as a result of which engine elements begin to wear out at an accelerated rate. Similar disturbances in the functioning of the engine can also occur due to improper belt tension.

Note! A break in the belt drive while driving not only negatively affects the condition of the engine, but can actually severely bend the valves. Repairing a car with such a breakdown often costs motorists five-digit sums of money.

In addition, drive tension that does not meet the standards accelerates wear of the main timing elements, the list of which includes:

Repair of each of the marked timing parts takes much longer than normal belt tensioning. Well, there is nothing to say about the cost, if you can tighten the drive yourself and completely free of charge, then you will have to pay for replacing the components of the mechanism.

How to lubricate the timing pulley without removing the belt

Usually the part is dismantled only for the purpose of replacement, and in this case the new roller is usually already filled with lubricant. It is easier to lubricate it without removing it, since dismantling takes too much time and effort.

First of all, use a screwdriver with a flat head or an electrode with a sharpened end to remove the boot.

Next, you need to take two two-cc syringes. The first is filled halfway with lubricant, that is, one cube is enough.

In order for the lubricant to come out of the syringe better, it is heated to 40 degrees. Hold the syringe needle, otherwise when pressed it may fly out from strong pressure.

When the contents begin to come out, the composition is pumped into the mechanism. To do this, insert a needle into the gap and, moving in a circle, apply the product in several areas.

The last injections will have to be done with a second syringe, since the piston of the first one may bend due to high pressure. More than half of one cube should fall into the mechanism. After lubrication, some of the composition may leak out.

Next, start the engine so that the lubricant is evenly distributed.

After turning, the lubricant will spread throughout the entire bearing rim. At the same time, there should also be no excess on the surface.

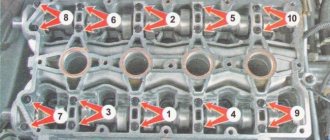

How to remove and lubricate the timing belt tensioner pulley

When using a standard technique that involves removing a part, first unscrew the protective cover.

Next, using the head attached to the extension, loosen the lock nut of the belt tensioner.

The belt tensioner rod is unscrewed using an 8 mm socket.

Then use a screwdriver to pry up the protective cover and unscrew the bolt, due to which the tensioner is attached to the roller.

Now you can remove the roller and disconnect the boot from it with a screwdriver. The removed part must be washed with solvent or kerosene.

It is important to put lubricant under all the balls, turning each of them. In this case, you do not have to use a syringe; you can perform the operation manually. After lubrication, assembly of the unit is carried out in the reverse order.

When does the belt need to be tightened?

Having considered the previous paragraph of the article, it was probably not difficult to understand that monitoring the correct functioning of the timing belt is quite important. In particular, it is worth keeping the belt drive tension at the proper level. By the way, stretching is carried out only in two main cases:

In situations that do not correspond to those noted above, it is simply not worth touching the belt drive of the mechanism. Especially if the motor runs stably, without pronounced problems.