How to replace a clutch release bearing

The replacement procedure is carried out in the following order:

- Remove the gearbox.

- Disconnect the ends of the clutch spring retainer.

- Remove the bearing from the guide sleeve.

- Disconnect the spring holder.

- Remove the old bearing and install the new one. Before installation, it is necessary to lubricate the bearing seat and bushing well.

The lifespan of the release bearings is 150,000 km, but this is with careful operation. When using a car by newbies or careless drivers (who abruptly release the clutch pedal or start with jerks), the service life ends after 50,000 km.

How to extend the resource?

To increase the service life of the device, you must drive on smooth roads. In our country, it is problematic to comply with this condition. Keep in mind that uneven roads destroy not only the vehicle’s chassis, but also the clutch system. Therefore, regular off-road driving is also dangerous for bearings. Don't make mistakes when operating your car. When the car is stopped at a traffic light, there is no need to depress the clutch pedal and engage first gear if you do not plan to move. This should only be done at the beginning of movement, since the part operates under high load conditions. Regular lubrication will increase the service life of the device.

How to choose a release bearing

Its quality determines how long you drive your car without taking it in for clutch repair. There is quite a large assortment of parts on the market, so below is a selection of bearings depending on some of the most popular car brands in the Russian Federation:

- Domestic Lada. These machines are equipped with a cable-driven part. This may seem surprising, but the competition here is very small: the number of participants does not exceed a dozen. Most often they buy AvtoVAZ products. In second place is Sachs from Germany, followed by Valeo. You can also mention Coram from Italy and TSN. Among the manufacturers in the Russian Federation - TZA (Tolyatti).

- Ford Focus (2nd generation). It has a hydraulic type bearing connected to the working clutch, so everything is replaced as an assembly. Removing and installing the entire system is quite problematic. There are approximately 15 manufacturers on the market. Of these, it is worth highlighting Sachs, which is the leader, Ford OEM, INA. Lucas, Valeo, FTE, Pilenga are also popular.

- VW Polo. There is also a hydraulic clutch here. But the bearing is simpler compared to the Ford Focus. There are approximately 14 suppliers on the Russian market, among which the leader is the little-known company SKF. Next comes JP Group (also unfamiliar), then Sachs. You can also note Luk, Dello, Automega, Vag, Febi and others.

Clutch master cylinder VAZ 2101

Stable operation of the clutch master cylinder (MCC) has a direct impact on the functioning of the gearbox and its service life, as well as the smoothness of gear shifting. If the hydraulic drive breaks down, control of the gearbox becomes impossible, as does further operation of the vehicle.

What is it for?

The main function of the GCS is to briefly disconnect the power unit from the gearbox when changing gears. When you press the pedal, pressure is created in the system, which acts on the clutch fork rod. The latter drives the release bearing, controlling the clutch.

How it works

The main components of the node are:

- outer cuff;

- sealing collar;

- union;

- stock;

- return spring;

- frame;

- case for protection.

The GCS housing contains a return spring, cuffs, working and floating pistons

Principle of operation

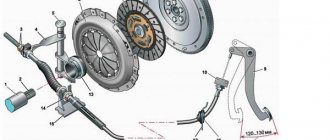

The hydraulic clutch consists of two cylinders - the main and the working (GC and RC). The operating principle of the hydraulic drive is based on the following:

- Liquid enters the GC through a hose from the tank.

- When the clutch pedal is acted upon, the force is transmitted to the rod by a pusher.

- The piston in the main center moves out, which leads to the valve closing and compression of the liquid.

- After the fluid is compressed in the cylinder, it enters the hydraulic system through a fitting and is supplied to the DC.

- The slave cylinder drives the fork, which moves the clutch with the release bearing forward.

- The bearing presses on the friction spring of the pressure plate, releasing the driven disk, after which the clutch disengages.

- After the pedal is released, the cylinder piston returns to its original position under the influence of the spring.

The pedal moves the pusher, which, in turn, moves the piston and creates pressure in the hydraulic drive system

Where is

The GCS on the VAZ 2101 is installed under the hood near the vacuum brake booster and the master cylinder of the brake system. There are also reservoirs near the clutch cylinder: one for the braking system, the other for the hydraulic clutch.

The GCS on the VAZ 2101 is located in the engine compartment near the vacuum brake booster and the master cylinder of the brake system

When is replacement needed?

The cylinder elements wear out over time, which leads to interruptions in the operation of the mechanism. Repair or replacement of the main circulation system is necessary when the following symptoms appear:

- airiness of the system;

- leakage of working fluid;

- wear of cylinder components.

The presence of air in the hydraulic drive system disrupts the performance of the system, making its operation impossible. Air can enter the hydraulic drive through microcracks in the sealing elements of the cylinder or in the connecting hoses. If, when checking the system, a constant lack of fluid in the expansion tank is discovered, you need to inspect the entire clutch mechanism, since fluid can leave not only the master cylinder. If the amount of fluid in the hydraulic drive system is insufficient, the required pressure to move the clutch fork will not be able to be generated. This problem will manifest itself in the inability to separate the engine and gearbox when pressing the clutch pedal. If the leak is caused by wear of the connecting hoses, then replacing them does not raise any special issues. If the problem is related to the GCS itself, then the product will have to be dismantled, disassembled and the cause found out, or simply replaced with a new part.

How does a release bearing work?

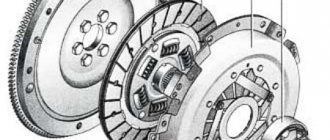

It is part of a structure that consists of a couple of elements:

- drive (pressure) disk (some call it a “basket”) with movable petals and springs, fixed on the crankshaft flywheel;

- driven disk connected through splines to the gearbox input shaft.

The bearing operation is controlled when the clutch pedal is activated. The whole node works like this:

- in the normal position, the drive disk presses the flywheel against the driven disk;

- when you press the pedal, the release bearing, thanks to the clutch fork, begins to move, affecting the petals;

- as a result of this effort, the two disks are separated and the engine is “disconnected” from the transmission;

- when the pedal is released, the paddles return to their previous position, which is why the discs connect again and the car moves on.

It is worth noting that the clutch can be mechanical or hydraulic. In the first case, the operation of the VP requires exclusively the physical effort of the driver. In the second, the bearing operates through hydraulic fluid. Its use makes pressing the pedal easier, but makes the clutch system more complex.

Purpose

To understand where the release bearing is located, you need to understand the purpose and design of the clutch. The clutch and all its parts belong to the vehicle's transmission. It ensures the transmission of torque from the engine to the drive axle and wheels, and must be located between these parts of the machine

But an important condition for the location is accessibility in its control by the driver. Most often this is the clutch pedal, less often the lever near the steering wheel

Using the clutch mechanism, the driver periodically disconnects the engine from the transmission. This allows you to stop the car, change the gearbox, and change the driving dynamics.

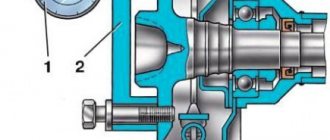

Installing the release bearing

Having removed the gearbox, we need to know the sequence of further actions, how to change the release bearing.

- First you need to assess the condition of the old part. If there are signs of operational wear on it, then you have correctly identified the cause of the abnormal operation of the gearbox. A faulty part, if turned, will produce a characteristic unpleasant crunch. If the causes of the malfunction are determined correctly, you can begin installing a new bearing.

- To do this, use a screwdriver to separate the ends of the coupling retainer. We disconnect the holders of the pressure ring - “spring petals”. We remove the release bearing from the clutch release clutch.

- Next, we check the correctness of fastening and installation. In normal operating condition, the release bearing should rotate around its axis freely without characteristic sounds. The protruding part of the bearing should be located towards the coupling. We use machine oil as a shaft lubrication element and install the bearing on the shaft.

- If the installation was carried out correctly, proceed to fastening using the clamping ring holder. We perform the entire sequence of actions in reverse order.

Bearing replacement is complete.

Bearing replacement procedure

If the bearing suddenly fails, you first need to take certain measures to get to the nearest service station or personal garage.

You can get to your destination in two ways: by means of a tug or on your own, but without using the clutch, that is, without pressing the pedal.

When moving on your own, you must follow special instructions:

- The first speed is switched on.

- The starter starts.

- After starting to move, you need to release the gas and move the gearbox lever to the 2nd speed position.

- After a little acceleration, you can switch to 3rd speed. In this case, you need to catch the moment when the speed of the running engine and the shaft are approximately equal.

This method should only be used as a last resort. There is a risk of “killing” the clutch basket and even the gearbox. It is advisable to find an opportunity to organize a tow truck.

As soon as the driver is at the service station, the car is sent for diagnostics, and then the necessary repair work is carried out.

If you have certain knowledge on automotive topics, if you do not want to spend money on the help of professionals, you can carry out the replacement on your own. To carry out this process, you will need to have at your disposal the necessary tools, a special place in the garage with a pit and an overpass. The procedure for replacing a bearing yourself is as follows:

- The vehicle is driven into the pit, the hand brake is applied and wheel chocks are installed.

- The terminals are removed from the battery, after which it is completely removed so that it does not interfere with work. At the same time, you need to disconnect the wire that connects the clutch housing ground.

- It is necessary to unscrew all the screws and bolts that securely fasten the car engine protection. The protection is disconnected. This creates unhindered access to numerous components of the clutch system.

- The gearbox drive rod, that is, the rocker, is unscrewed. For this purpose, use a 13 key to unscrew the clamp bolt and move it apart. After this, the drive is disconnected from the main gearbox.

- The sensor that turns on the rear lights is disconnected, as well as the clutch cable.

- The hub nuts are loosened and the front wheels are raised. They need to be removed and the hub nuts must be completely unscrewed. After this, the ball joints are unscrewed and the hubs are turned out so that it becomes possible to dismantle elements such as boots and clamps.

- It is necessary to place a support under the engine so that after removing the gearbox it does not fall. After this, all the screws that secure the gearbox to the engine are unscrewed, and the brackets for securing the gearbox are also unscrewed. It is advisable to carry out this work together, as this is a fairly significant part of the car. In the process of pulling out the device, you need to make sure that the input shaft does not touch the petals.

- It is necessary to remove the ends of the spring clamp using a screwdriver. After this, the clutch is pulled out.

- The petals are moved back a little and the old bearing is removed.

- Using the reverse sequence of actions, you need to install the new part in place. The bearing must be installed on the coupling so that all protruding components are directed towards the coupling.

- The new part is fixed using the clutch holder while using a compound such as grease for the clutch release bearing.

After replacing the bearing, the gearbox itself is installed, also in the reverse order. You need to put the ball joints and CV joints in place, and tighten the hub nut. Then the wheels are installed, special wheel bolts are tightened, and the car is lowered to the surface. Once the car is on the floor, you need to tighten them along with the hub nuts.

At the end of the work, you need to pour the oil back into the gearbox, or better yet, replace it with a completely new product.

The old bearing must also be replaced exclusively with a new one.

In this case, you need to pay attention to the manufacturer of the part. If multiple clutch elements are from different companies, a slight imbalance may occur during operation.

Selecting a complete clutch system kit is relatively easy. The main thing is to focus on popularity among buyers, reviews left by drivers, and the reputation of the manufacturer and supplier. The best option would be to purchase a complete set from one company.

Replacing the clutch release bearing

The first thing you need to do is dismantle the gearbox to gain access to the desired unit. On some cars you have to remove the starter if it gets in the way. How to do all this? Stages:

- Drive the car into a viewing hole or use a lift.

- Place the car in handbrake and place safety chocks under the wheels.

- Disconnect the terminals from the battery and remove the battery from the car.

- Unscrew the ground from the clutch housing.

- Remove the crankcase protection.

- Remove the gearbox drive rod (it’s called the “link”), to do this you will have to unscrew the clamp bolt and straighten it.

- Disconnect the wiring from the sensor that turns on the reversing lamps;.

- Remove the cable that pulls the clutch lever.

- Loosen the hub nuts, jack up the car and remove the wheels, then unscrew the hub nuts completely, disconnect the ball joints, clamps, and boots.

- Place a support under the engine to prevent it from falling after removing the gearbox.

- Unscrew the bolts securing the box to the engine and pull it out (it’s best to do this with an assistant).

- Pull out the ends of the clamp with a flat-head screwdriver and remove the coupling.

- Remove the bearing from the transmission shaft.

- Remove the worn VP from the guide bushing by pressing out the 4 tabs of the lock.

- Carefully inspect the part for damage: it is quite possible that the cause of poor clutch performance is not the release bearing.

- A working part should rotate freely, without distortions or play.

- Lubricate the CV joint 4 bushing (with a thin layer).

- Insert the bearing into it and secure it with the holder.

- Place the assembled “system” onto the gearbox input shaft.

When assembling, make sure that all protruding parts are facing towards the coupling.

“Minor troubles”

Noise and squeaking also indicate clutch malfunctions. In this case, the release bearing becomes unusable. Like any other bearing, it begins to make noise. But if you press the clutch pedal, the basket will open and stop rotating (the engine is running, the car is stationary), and accordingly the noise will disappear. This is the simplest diagnosis. Otherwise, the bearing may simply fall apart and damage the basket.

Joker

There is one more part left - the clutch fork. If it breaks, bends or cracks, then no clutch will be released. Accordingly, a broken fork may have symptoms similar to other problems when the gear cannot be engaged.

Signs and causes of release bearing failure

The clutch, or rather the clutch release bearing, breaks due to the fact that it experiences uneven loads while the clutch is depressed and the bearing moves back along with the driven disk. Because of this, it is not recommended to keep the clutch pedal depressed.

If a knocking sound occurs when you press the clutch pedal, this indicates wear on the clutch bearing. As a rule, if there are problems with the bearing, you can still use it for some time.

What fan drive is on your car? Check out the working principle of a viscous fan coupling for an alternative.

How to recognize a broken release bearing?

Like other car parts, the unit in question does not last forever and is subject to natural wear and tear. The release bearing operates when you press the pedal, so the service life of the device depends on the frequency of operation.

In addition, the release bearing breaks faster for car owners who do not remove their foot from the clutch pedal. A breakdown can be recognized by many signs, which, if ignored, can cause the mechanism to fail.

Malfunctions of the clutch release bearing can be recognized by the following symptoms:

- The appearance of extraneous sounds.

- When you press the pedal, there is a noise, a whistle.

- Difficulty engaging gears.

It is not recommended to ignore the breakdown, because the result may be clutch failure and the inability to operate the car. Problems with the release bearing are usually associated with wear.

The key things here are:

- Operating conditions (ingress of dirt, water or other foreign objects).

- Mechanical load level.

- Temperature conditions and vibrations.

A characteristic sign of a breakdown of the release bearing is a “death” squeal, signaling the need to replace it; if this is not done, the bearing may fall apart or jam.

Causes of bearing failure

With relatively careful use of the car, even on uneven roads, the part can last quite a long time. Problems arise much faster if the motorist prefers a special, harsh driving style. Along with this form of movement in transport, several other reasons for the failure of a part can be noted.

One of the most basic is improper handling of the clutch pedal. Most modern drivers make the same mistake while driving - when they press the pedal, they do not release it in time.

Holding the pedal fully depressed for a long time will place a serious load on the bearing, which it is not designed to withstand.

Another fairly common reason for bearing failure is natural wear of the part. On average, the service life of a part when used carefully is 150 thousand kilometers. In the presence of provoking factors, this process occurs much faster.

This is interesting: The design of the main brake cylinder and 5 main signs of its failure

Among other reasons contributing to the reduction in the total working life of a part, the following factors can be identified.

- Temperature changes.

- Long-term use of a car in conditions of high humidity.

- Frequent use of the vehicle in special off-road conditions.

- Various mechanical loads.

If you do not pay attention to the car, if you ignore the signs of bearing wear, the owner of the vehicle may face serious problems, with complete failure of the clutch assembly.

If the part itself is relatively inexpensive and replacing it does not take much time, then updating the entire clutch system will require spending much more resources.

Signs

The main signs of an impending breakdown are its slipping and incomplete shutdown.

Clutch system

During incomplete shutdown (the pedal is depressed), it is difficult to change gears with the engine on. The appearance of noises and crackles when shifting gears, increased free play of the pedal. When the clutch slips when the pedal is released, a burning smell is felt, the vehicle's movement is deteriorated, the engine overheats, and fuel consumption increases.

If you notice such signs of a malfunction, if you cannot fix the problem yourself, immediately go to the nearest service station. If you get there on your own, then move slowly, don’t accelerate too much and be very careful when changing gears. It would be a good idea to use a double squeeze when switching.

Clutch pedal

You can also resort to a special technique. When shifting to a higher gear, the clutch must be depressed and the gear lever must be held in neutral for a while. Next you need to release, then squeeze again, then turn on the gear you need.

When switching to a lower gear, the gear lever, as in the previous case, must be held in neutral. Next, we release the clutch and lightly press the gas, then squeeze it again and go to the required gear. If you can master this kind of gear shifting, you will significantly reduce the load on the clutch and extend the life of the gearbox.

Principle of operation

The release bearing can be either push-action or pull-out. It turns the mechanism on and off. The clutch basket is connected to the disc. Today two types of these bearings are produced:

- Roller;

- Hydraulic.

The clutch is used to smoothly disengage the engine from the transmission when changing gears. This approach protects transmission elements from excessive overloads and malfunctions.

One side of the release bearing is made as a round pressure pad, comparable to the diameter of the release springs, located in the center of a part called the clutch basket.

Roller

The release bearing is located on the input shaft protruding from the gearbox, but it is attached to the shaft protective casing and drives the drive fork (rocker arm). The latter presses on a pressure mandrel equipped with special protrusions. The hub moves freely to the input shaft. Damper springs located inside dampen torsional vibrations, they ensure smooth activation.

The pressure plate with the diaphragm spring and the housing form a block called the clutch basket. To create the required force, a diaphragm spring presses on the pressure plate. Inside it is made like metal petals, which are acted upon by a release bearing. It is placed on the axis of rotation as a transmission device connecting the drive to the clutch. The fork (rocker arm) is designed to move the release clutch with the bearing.

Hydraulic

Repair and replacement of the clutch slave cylinder

When choosing a spare part to replace the clutch cylinder, you should pay attention to the material from which the part body is made. As noted earlier, such material can be cast iron, steel, aluminum or polymers

Today, many manufacturers offer aluminum and even polymer cylinders, but such parts are less reliable.

There are several types of clutch cylinder malfunctions that will require rod repair:

- leakage of working fluid through worn seals or connecting tubes with defects;

- presence of cracks in the cylinder body;

- broken working cylinder springs.

The rod consists of several components, each of which is subject to wear. Its parts - pusher, piston, cuffs, spring - experience high loads during operation, so there is a possibility that they may fail.

Symptoms of a faulty clutch cylinder:

- a decrease in the level of brake fluid in the cylinder reservoir and the appearance of spots under the car while parked;

- the pedal fails and the clutch works intermittently;

- There are problems with shifting gears.

Experts advise, first of all, to pay attention to the travel of the clutch pedal. If it runs too softly, this is not yet a reason for urgent repairs, but the operation of the cylinder should be diagnosed.

To check it, you need to bleed the clutch hydraulic drive. If there are air bubbles in the working fluid, you should understand the reasons for their appearance. As a rule, air gets inside the rods of the clutch slave and master cylinders due to depressurization of the sealing collars.

As noted earlier, repairing and replacing the clutch slave cylinder is not a very difficult task. This part is most often located on the gearbox housing.

First you need to unscrew the fastening bolts, disconnect the pusher from the fork and begin dismantling the hose that comes from the main circulation center.

Since there is working fluid in the master cylinder, the hose should be plugged (for this you can use a plug of the appropriate diameter). There is also another opinion - you need to disconnect the hose to completely drain the brake fluid (it is believed that this will help flush the clutch hydraulic system from dirt).

After dismantling, the clutch master cylinder must be disassembled and, if possible, repaired. If this part has a metal body, then it can be fixed in a vice, but if the part is plastic, then you need to be careful not to damage it.

After disconnecting the air valve, it is necessary to remove the outer cuff. After this, taking into account the design features of the cylinder, it is necessary to provide access to the rod and remove the retaining ring. After disassembling the part, you must ensure that there is no damage to the spring, rod or defects of the cylinder mirror.

All components must be washed with brake fluid. We noted earlier that kerosene, gasoline, motor oil or water cannot be used for this purpose (these liquids contribute to the swelling of rubber elements).

When assembling the cylinder, all seals and seals should be replaced with new ones.

Repair of the clutch master cylinder will not be possible if:

- body cracks;

- noticeable wear on the inner surface of the body, which appears as a result of defects in the rod.

In this case, you need to completely replace the faulty clutch cylinder with a new part.

After replacing the clutch master cylinder, do not forget to bleed the system.

The method for bleeding the hydraulic drive system after replacing the clutch slave cylinder does not differ from that described previously for the hydraulic clutch. At the same time, in some car arches (for example, on Fiats), the clutch system is back-pumped. To do this procedure yourself you need to prepare:

- a hose that fits tightly onto the exhaust valve;

- a large syringe, the diameter of the nozzle of which corresponds to the size of the hose;

- a wrench to remove the air release valve.

First, unscrew the cap of the reservoir with the working fluid and draw it into the syringe. You need to expel all the air balls from the syringe, and then connect its spout with a hose, the second end of which is connected to the release valve. After this, you need to unscrew the valve 2-3 turns, press the syringe and pump the brake fluid into the clutch cylinder. To prevent air from entering the system, you must first tighten the valve and only then remove the hose.

This sequence of actions must be performed several times until all the air is forced out of the hydraulic drive system into the tank. After this, you need to depress the clutch pedal about 10 times and, if necessary, adjust its travel height.

Malfunctions

To find out what the malfunction is, you need to depress the pedal (the engine is running). If after this the noise disappears, then the part is not at fault. These signs indicate problems with the gearbox and it needs to be repaired. When the noise continues to intensify, the fault is related to the bearing and it urgently needs to be replaced.

Torque acts on the clutch release bearing only at the moment of pressing. When the pedal is depressed, it goes back together with the driven disc (clutch basket). And then, if the gear is engaged and the pedal is held down for a long time, then uneven loads act on the part. This usually leads to rapid wear, but if all operating rules are followed, repairs will not be needed for long.

But the knocking sound when the clutch pedal is depressed (the engine is running) can intensify in cold weather. Then it's quite possible there's no need to worry. This part is made of heavy-duty steel with a low linear expansion coefficient. The glass, where all the bearing elements are located, is, on the contrary, subject to temperature influences, so knocking may occur periodically. This does not indicate a system malfunction

How to determine the state of a VP

The main signs of a component malfunction are extraneous sounds (the bearing makes noise or whistles) when the clutch pedal is fully depressed and the engine is running. To check the bearing, depress the clutch at different speeds. It is advisable to perform this operation together; if the part is noisy, it is better heard not from the cabin, but from the hood. If it is noisy only in a small rpm range, then most likely the problem is some kind of poorly tightened nut. If the part makes noise at any engine speed, then this indicates a bearing failure, so it needs to be replaced. If you hear these signs while driving on the highway, do not be alarmed. From malfunction to jamming, it will work for at least 10 thousand kilometers. After all, the bearing makes noise due to wear of the rollers and the vibration caused by this, and the principle of its operation is such that it is very far from noise to destruction.