The car's clutch mechanism itself is quite simple and boasts an impressive margin of safety. Due to uneven wear, some of its components fail earlier than others, which entails breakdown of the entire mechanism. One such component is the clutch basket. Let us immediately note that a basket is understood as a set of several parts. We will consider the entire tandem, and for simplicity we will simply call it a basket. Next, he will tell you in more detail about the principle of operation of the clutch basket, its main faults and methods for finding a new spare part.

The design and principle of operation of the clutch

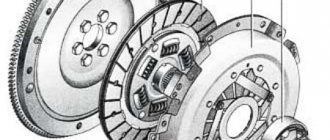

To fully understand how the basket is designed and what functions it performs, you should start by considering the entire clutch mechanism. We remind you that the clutch is one of the most important elements of a vehicle transmission, which connects the engine flywheel to the gearbox. The main clutch elements include:

- Flywheel;

- Driven and pressure disks;

- Clutch with release bearing;

- Shutdown plug;

- Working and master cylinders;

- Special springs (diaphragm / pressure).

Other important elements directly related to the clutch are pipelines, pedal, crankcase, input shaft gear, crankshaft, drive shaft, protective casing (housing). The clutch drive can be hydraulic, mechanical, electric, or combined. All details are collected in the so-called. clutch housing, which is connected to the engine crankcase.

The principle of operation of the clutch is not entirely clear to many car enthusiasts, even if they understand how to interact with this mechanism. We invite you to familiarize yourself with his work step by step. The main control elements of the mechanism are the clutch pedal and the gear shift knob. Here's how it works:

- Moving the lever to neutral, depressing the clutch and selecting a gear. Result: a running engine begins to rotate the flywheel, but the driven disk has not yet come into contact with the flywheel - while they are open;

- The driver begins to slowly release the pedal. Result: the flywheel engages with the driven disk through the action of springs; the rotation speed of the disk begins to increase and torque is transmitted to the drive wheels;

- The driver continues to hold the clutch pedal (does not release it). Result: the rotation of the disk and flywheel is synchronized and the car picks up speed;

- The driver finally releases the pedal. Result: the clutch is fully engaged; synchronized mechanisms ensure the transmission of torque from the engine to the gearbox, and then to the drive wheels.

It is worth noting that there are several options for implementing clutch systems. The most practical is considered to be a dry single-disc with a constantly engaged clutch. Such a system is easy to use, has a long service life and a fairly simple design, which facilitates the production and maintenance of basic elements. And now we suggest returning to the basket, which we undeservedly ignored when considering the design of a car clutch.

Clutch: disc, basket and release

So, in general terms, the design of a traditional mechanical clutch (single-plate) assumes the presence of the following elements:

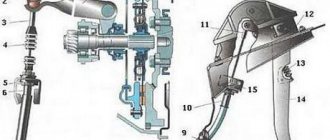

- clutch pedal inside the car;

- drive mechanism, which may be hydraulic, pneumatic or mechanical;

- clutch fork;

- release bearing;

- driven disk;

- clutch basket;

The moment the driver presses the pedal, the force is transmitted to the clutch fork. Then, through the release bearing, the force is transmitted to the petals of the basket. Next, the basket presses the driven clutch disc away from the flywheel, thereby opening the gearbox and internal combustion engine, that is, the power flow is interrupted. Let us add that in robotic gearboxes it is not the driver who is responsible for pressing the clutch, but the actuators, since there is no clutch pedal.

Let's move on. If we look at the clutch basket in more detail, it is important to understand that it is this element that makes it possible to connect and disconnect the disc and the flywheel. In other words, the basket engages/disengages the clutch. In this case, damage, wear, deformation and other defects of the basket lead to the fact that the entire mechanism begins to work incorrectly.

The clutch basket itself is a single piece that includes the pressure plate, diaphragm spring and housing. The basket is also in close contact with a number of parts. The basket casing is bolted to the flywheel. The return spring, which is mounted in the basket, interacts with the release bearing.

The pressure plate allows you to connect the driven disc and the flywheel. When the clutch is disengaged, the pressure plate presses on the driven plate, which is in contact with the flywheel.

If the clutch is disengaged, there is no pressure plate pressure on the driven disc, that is, the disc rotates separately from the flywheel. By the way, the pressure plate is connected to the basket casing using special leaf springs (tangential springs). When the clutch is disengaged, the springs act as return springs.

Also in the basket design you should highlight a diaphragm spring. This spring creates the necessary force to effectively connect the disc and flywheel. It turns out that the transmission of torque from the internal combustion engine to the gearbox will depend on the clamping force.

We also recommend reading the article on how to change gears without a clutch. From this article you will learn what to do if the clutch on your car does not work and how to turn on the speed if you need to continue driving the car without pressing the clutch.

The diaphragm spring looks like petals and is attached to the edge of the casing. In the inner part of the casing, the spring is attached to the casing with bolts or support rings (depending on the design features). The clutch release bearing presses against the ends of the paddles on the outside of the clutch basket. This pressing allows you to ensure that the spring inside the basket does not press on the pressure disk itself.

Also within the framework of this article, it should be noted that clutch baskets can be of different types. Among the main types, one can distinguish the exhaust and push type. However, the principle of their operation is somewhat different.

As a rule, of all types of release baskets, it is the basket with the push principle that is used most often in the clutch device. The main feature is that when the clutch is engaged, the petals of the basket move closer to the flywheel. The design is simple, proven and reliable.

If the machine has a basket with a traction operating principle, then the petals move from the flywheel. The second type of baskets is smaller in size and is often installed in order to save space in the engine compartment.

There are also baskets, the design of which differs from the standard one. Typically, such baskets are needed for powerful forced internal combustion engines and have a reinforced diaphragm, which makes it possible to significantly increase the clamping force (up to 1.5 times or more compared to the standard).

For this, the basket and individual elements are made of durable alloys, and the geometry of the spring itself becomes more complex. Typically this type of basket is found on supercars, sports cars and non-production vehicles.

More information about the functions and design of the clutch basket

One of the main components of an automobile clutch is considered to be the basket, which is enclosed in a single housing with a number of other components. The main task of the basket is to disconnect and connect the flywheel to the pressure plate, i.e. disengaging and engaging the clutch at all. If the basket malfunctions, the entire mechanism will stop working normally or will fail altogether. Here it is worth returning to the clutch design again to better understand the role of the basket. Clutches are divided into the following types:

- Electromagnetic;

- Hydraulic;

- Frictional;

- Combined.

As mentioned above, without a clutch, normal transmission of torque from the engine to the gearbox and to the drive wheels is impossible. By the way, the torque is also converted in the gearbox and some intermediate elements of the transmission. If the clutch is engaged, then this torque can normally be transmitted to the rest of the transmission and chassis elements. In the “engine – drive wheels” chain, the basket takes on the following tasks:

- Transfer of torque without significant losses;

- Smooth connection or disconnection of the transmission with the engine when manipulating the clutch pedal;

- Reduced loads on the engine and the crankshaft in particular;

- Reduced vibration vibrations that negatively affect the engine, transmission and main components of the clutch mechanism.

Most passenger and medium-sized cars are equipped with a dry single-plate clutch. The difference between a dry clutch and a wet one is that the friction of the parts occurs in an air environment rather than an oil environment. The key elements of the basket are:

- casing;

- Diaphragm spring with petals/coil compression springs;

- Pressure disk.

The most characteristic element of the basket are the petals, otherwise called pressure plates. They also act as release levers. Usually the number of petals in a basket is twenty. In this case, baskets are divided into two types:

- Lever;

- Diaphragm.

The most practical and reliable design is considered to be the diaphragm one, although in fact its main advantage is its structural simplicity. Lever baskets can ensure reliable clutch engagement almost regardless of crankshaft rotation speed. However, diaphragm baskets are most widespread. They work like this:

- If the clutch pedal is released, the pressure plate is pressed against the driven one by the springs and torque can be transmitted to the gearbox from the engine;

- When the driver steps on the pedal and engages the gear, the release bearing pushes the petals, the short arms of which pull the pressure plate along with them, and then the clutch disengages (the discs move apart);

- When the pedal is released, due to the elasticity of the diaphragm spring, the pressure disk is pressed against the driven one and the transmission of torque is resumed by bringing the disks together.

The baskets work in a similar way in both single- and double-disc clutches. There are differences, but they are insignificant and more interesting here is the work of third-party clutch elements. In particular, the increasingly popular electromagnetic clutch release systems, the operation of which we will not consider in this material.

Clutch device

There are single-disc clutches and double-disc clutches. The most popular is single-disk.

It consists of:

- clutch baskets;

- driven disk;

- release bearing;

- clutch forks;

- drive, which can be either hydraulic, mechanical, or pneumatic;

- clutch pedals inside the car.

Operating principle in simple words

The driver presses the clutch pedal. Driving instructors call this action pressing the clutch. The pedal transmits force to the clutch fork, which acts on the release bearing. Through it, the force is transferred to the petals of the basket.

The basket presses the driven clutch disc away from the flywheel, that is, it disconnects (separates) the engine and the gearbox. In this case, no matter how the driver presses the gas, no force is transmitted to the box.

In cars with a robotic gearbox, there is a clutch, but there is no pedal, because it is not the driver who is responsible for squeezing the clutch, but the actuators of the robot.

The cart consists of:

- pressure plate;

- diaphragm spring;

- casing.

The basket casing is bolted to the flywheel. The return diaphragm spring is attached to the basket and acts on the release bearing. As for the pressure plate, it connects the driven disk to the flywheel.

When the clutch is engaged, that is, when the pedal is not pressed, the pressure plate presses on the driven disc, and the driven disc is connected to the flywheel.

When the clutch is disengaged, that is, when the pedal is pressed, the pressure plate does not press on the driven disk and the gearbox does not depend on the engine. The pressure plate is connected to the basket, or rather to the basket casing, by plate tangential springs. After releasing the clutch pedal, the springs return to their original position.

The clutch design also includes a diaphragm spring. The spring exerts a force and connects the disc to the flywheel. The stronger the disc is pressed against the flywheel, the better the torque is transmitted from the internal combustion engine crankshaft to the box.

Externally, the diaphragm spring looks like petals and is attached to the edge of the casing. In the inside of the casing, the spring is bolted to the casing. There is also a design where the springs are secured with support rings. The release bearing presses on the end of the petals on the outside of the basket.

Similar articles

Faulty clutch disc damper springs. clutch problems: learning to identify and fix

There are two types of clutch baskets:

- Exhaust.

- Push.

The push basket is more common due to its simplicity of design and proven reliability.

The exhaust basket is smaller in size. With a push basket the petals move towards the flywheel, and in a pull basket they move away from the flywheel.

Classification of diaphragm baskets

Structurally, even simple diaphragm clutch baskets can differ from each other. As practice has shown, a simpler design is more reliable, but its main disadvantage is its greater thickness. According to the principle of operation, baskets are divided into:

- Push;

- Exhaust.

In the case of pressure baskets, interaction with the clutch mechanisms is carried out by moving the petals in the direction of the flywheel. If we are talking about exhaust baskets, then the petals, on the contrary, are displaced from the flywheel. By the way, this particular design can boast of the smallest dimensions - it has less thickness and allows you to save a little space under the hood.

It is customary to place baskets with a powerful diaphragm spring, which has significant downforce, into a separate category. As a rule, the downforce of such diaphragms is 50% greater than that of standard diaphragms. They differ from the latter in more complex geometry and other materials. It is recommended to install special baskets exclusively on tuned cars. They guarantee faster clutch response and better transfer of power from the engine.

Basic clutch malfunctions

So that we understand what we are talking about. Clutch actuators include:

clutch basket – clutch pressure disc; release bearing - clutch release clutch combined with a bearing. Replacement and repair of the clutch basket, as well as replacement of the clutch release bearing, are simplified by the fact that the clutch parts come from the manufacturer as a set, and there is no point in changing them separately. Yes, and car maintenance technology recommends such a complete replacement. The first signs of a clutch malfunction: the car does not gain full power, when you press the clutch pedal you hear a noise, the car jerks and slips while moving away, and so on. Clutch malfunctions occur due to natural wear and tear of parts, but... As a rule, novice motorists do not get to this point. Most often, we ourselves are to blame for clutch malfunctions: incorrect gear shifting, the driving mode is chosen illiterately, sometimes emotions let us down (especially when trying to prove who starts faster from a traffic light, etc.), the friction material on the clutch disc is worn out. This is due to loads or oil getting on the linings from the engine or gearbox. As a result, the necessary connection between the clutch basket and the flywheel does not occur. Conclusion: clutch basket repair. The clutch release bearing has broken. As a result, the clutch basket petals break. The cause of the characteristic noise when squeezing the clutch. The sensor springs of the clutch disc fail, as a rule, due to your attempts (voluntary or involuntary) to start with reckless slipping.

So, the main clutch malfunctions: the friction material on the clutch disc is worn out. This is due to loads or oil getting on the linings from the engine or gearbox. As a result, the necessary connection between the clutch basket and the flywheel does not occur. Conclusion: clutch basket repair. The clutch release bearing has broken. As a result, the clutch basket petals break. The cause of the characteristic noise when squeezing the clutch. The sensor springs of the clutch disc fail, as a rule, due to your attempts (voluntary or involuntary) to start with reckless slipping. When starting to repair or replace the clutch basket or clutch, consider purchasing an engine main oil seal and an input shaft oil seal. This will be needed so that, after repairing the clutch, you do not have to dismantle the gearbox again due to their leakage.

Briefly about malfunctions

As the reader has probably already guessed, the pressure plate, connecting elements and clutch basket cover have a long service life. Since the pressure plate is in constant operation, it is the one that fails first. The petals may also become deformed. If they wear out, serious damage can occur to both the disc and the release bearing. It can be difficult to identify a fault without disassembling the clutch housing. Typically, failures of the clutch drive or the clutch itself are identified. In the case of a basket (a structural element of the entire system), the driver can pay attention to:

- Noise when manipulating the clutch pedal. Note that the noise can be caused by wear on the drive plate and even the release bearing. Inspection of the basket petals is highly recommended;

- The appearance of an unpleasant odor. It is caused by extreme wear of the driven disk, but this malfunction can also “hit” the clutch basket;

- High degree of slippage. You can detect slippage when you engage an upshift on the handbrake - normally the engine should stall when you press the gas pedal;

- Incomplete release of the clutch. It may indicate problems with other clutch elements, so disassembling the unit is recommended here.

A final diagnosis can only be made by disassembling the mechanism. Attention should also be paid to the discs and release bearing. Examine the petals of the basket. They must be intact, and their wear should not exceed 0.8 millimeters . For lever baskets, check the integrity of the arms. If the pressure plate shows signs of warping (changes in the original geometry), there is a high probability that you will have to replace the entire basket. If the clutch operates jerkily, and the driven disk, its hubs, damper springs and engine mounting mounts are normal, we can confidently speak about critical wear of the pressure disk.

The following malfunctions may occur in the clutch basket:

- The petals (otherwise known as pressure plates) may break;

- The pressure plate may be subject to wear;

- Rivets and fasteners may become worn and play may increase.

Basically, when repairing a clutch, the faulty element is always replaced. It should be clarified that experts in this field recommend replacing the clutch basket together with the driven disk, as well as the release bearing. This must be done due to the fact that the clutch part is constantly subject to loads, as well as uniform wear. Therefore, we can conclude that if you replace only one clutch basket, you will still have to replace the driven disk, and after that the release bearing. And when any clutch repair operation is performed, removal of the gearbox is a mandatory factor for this. The only exception is adjustment work.

Thus, we can conclude that it is much wiser to replace the entire assembly at once. Of course, much depends on how the driver drives in the trouble-free operation of the clutch, as well as in correctly made adjustments. In addition, you should not install a clutch basket on your vehicle, which was produced in an unknown place, as people sometimes say, “in artisanal conditions.” You need to purchase car parts only from trusted and good companies. At the moment, the best manufacturers of clutch baskets have proven themselves to be: Kraft, MecArm, SACHS, VIS (Vazinterservice) and LuK.

Correct operation

Despite the apparent resistance of the clutch basket to various influences, its petals can quickly wear out or even become deformed. Their accelerated wear is promoted by:

- Overheating of the pressure plate due to frequent and prolonged clutch slipping;

- Ignoring the breakdown of the clutch slave cylinder;

- Oiling of the petals due to wear of the oil seal;

- Jamming of the release system;

- Ignoring the problem of lining wear;

- Incorrect installation of the part, in particular, incorrect alignment on the flywheel.

Do not forget also about the general rules for operating a car. For example, you need to check whether the handbrake is turned off before driving. Warm up the engine for at least a couple of minutes and do not rev it up unless absolutely necessary. To extend the life of the clutch during temporary stops, such as at a traffic light, it is worth setting the gear to neutral and engaging the clutch (releasing the pedal).

Spare parts for Volkswagen passat

Clutch basket

PASSAT sedan (B5, 3B2) (10.96 - 11.00)

Spare parts for Honda civic

Clutch basket CIVIC VIII sedan (FD1) (09.05 - 12.12)

Choosing a new clutch basket

Usually the clutch basket is not sold as an independent part, but comes complete with a bearing and discs. This set is called a clutch kit. However, if you are faced with wear on the diaphragm spring, you are unlikely to need all the other parts in the kit. Sometimes the basket is sold separately from all other clutch components. You can search for it by:

- VIN code of the car;

- Basic parameters of the car;

- Code of the required spare part.

Since a car enthusiast usually does not know the code for a suitable cart, it is better to search for it using the car parameters in online stores. For example, on, where a simple and intuitive system for searching for spare parts is implemented, taking into account such vehicle parameters as make and model, engine parameters, year of manufacture. We advise you to pay attention to the manufacturer. The following companies offer the highest quality baskets:

- Valeo (France);

- LuK (Germany);

- Exedy (Japan);

- Sachs (Germany).

The same thing that LuK and Sachs have is offered by the German company INA. Cheaper analogues can be found from Mecarm (Italy) and JP Group (Denmark). We do not recommend saving much on clutch components, however, in the case of a basket, you can still save wisely. A good option would be a clutch from the Japanese ]Exedy[/anchor] or the most affordable analogue under the name of one of the brands of the German Schaeffler, which are listed above.

What you need to know about the clutch basket.

Every motorist is familiar with the concept of a clutch basket. It is a clutch part that is attached to the flywheel. Thanks to it, adhesion to the driven disk is ensured. The basket consists of three main components. This is a nickel, a spider and a slab.

Many people sometimes do not quite understand why they need to change it. However, if you look closely, its appearance changes somewhat over time. For example, the legs of the basket can be at different heights. If this is the case, then this will be the first sign that this part needs to be replaced or repaired. Due to different heights of the paws, different speeds may occur when changing gears. Because in this case the clutch will not disengage completely. At the same time, it’s worth mentioning right away that you should pay attention to the paws even when buying a basket. It is not uncommon for drivers to purchase parts that are already damaged. If you notice any curvature of the paws, it is best to refuse the purchase. Particular attention should be paid to bearings. If you do not monitor its condition, it can significantly damage the basket. At first he just begins to whistle and make noise. Subsequently, serious destruction of the metal occurs. In some cases, when repairing a vehicle, you may find that the clutch basket has turned blue. As a rule, this happens in cases where severe burning was carried out. Mostly, training cars that were used to learn to drive are subject to such deformations. The longer you postpone the procedure for replacing the old clutch basket with a new one, the more financial resources you will have to invest in repairs. Any vehicle owner should always remember this. Only timely diagnostics and repairs will save not only money, but also personal time. Currently, the Luk clutch basket or any other can be purchased at any online store that sells automotive spare parts and components. Electronic catalogs provide a unique opportunity to make a very profitable purchase - to purchase high-quality parts at lower prices compared to regular stores and luxury showrooms. In addition, if there are no high-quality auto stores in a small locality, then electronic catalogs are, one might say, the only opportunity to purchase the necessary parts. Couriers will be able to deliver goods anywhere in the country at any convenient time. However, it is worth saying that the car owner, if desired, can always use Russian Post.

Conclusion

The clutch basket is an important element of the clutch mechanism. If it malfunctions, it will not work normally, and operating the vehicle will not only be difficult, but can also become dangerous. Due to the long service life, the key elements of the basket wear out greatly only after 120-150 thousand kilometers. Selecting a new basket is easy, and the part itself costs relatively little money. Please note that it is not repairable and even its maintenance is a big question. A worn basket should be replaced as soon as possible.