The term clutch “floats” means that the clutch does not disengage completely when the clutch pedal is depressed. When the clutch pedal is released, it is constantly on. After pressing the pedal, the force is transmitted through the cable and fork to the release bearing, which presses on the petals of the “basket” pressure spring. The spring acts on the drive disk, which stops pressing the driven disk against the working surface of the flywheel. The transmission of torque from the engine to the gearbox is interrupted. You can change gears.

If for some reason the driven disk is not sufficiently moved away from the flywheel, shifting forward gears will be difficult, and the rear gear may engage with a crunch and crackle. Let's look at the causes of this malfunction (the clutch is moving) on VAZ 2108, 2109, 21099 cars.

Reasons that the clutch is leading

Clutch drive not adjusted

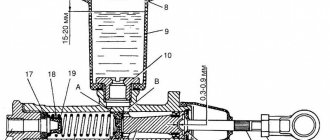

Full pedal travel is insufficient. The clutch pedal is located below the brake pedal. It is necessary to adjust the drive so that its stroke is 12.5 - 13.5 cm, and it is approximately level with the brake pedal.

adjusting the clutch drive by rotating the adjusting nut

Drive cable jamming in sheath

Over time, the drive cable may wear out, the wires in it become frayed, which makes it very difficult to move in the sheath. As a result, when you press the pedal, the clutch does not disengage completely (drives).

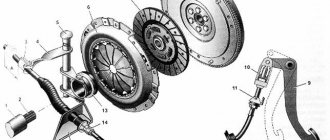

The driven disk is faulty

The driven clutch disc may be warped (its end runout is more than 0.5 mm). The driven disc hub may bind to the input shaft splines if they are heavily dirty or worn. In any case, the driven disk will not move away from the flywheel to the required clearance.

clutch driven disc for VAZ 2108, 2109, 21099 cars

The flywheel or pressure (drive) disk of the basket is faulty

Severe scuffing on the flywheel or drive plate working surfaces may prevent the driven disc from rotating freely.

clutch “basket” for VAZ 2108, 2109, 21099 cars

The clutch pressure damper spring is faulty

Severe wear of the ends of the spring petals at the point of contact with the release bearing.

ring wear on the petals of the clutch pressure spring

Notes and additions

— In a number of cases, difficult gear shifting on VAZ 2108, 2109, 21099 vehicles can be caused by reasons not related to the clutch. For example, breakage, deformation, incorrect adjustment of drive elements of the gear shift mechanism.

More articles on the clutch of VAZ 2108, 2109, 21099 cars

Assessing the advantages and disadvantages of their cars, owners are increasingly talking about the engine and suspension. Much less often in such conversations you can hear about the gear shift mechanism. The reason for this unpopularity is that the lack or reserve power of the power unit reminds itself regularly, and the driver quickly gets used to the controls. However, it is impossible to do without periodic adjustment of the friction clutch control during operation.

When do you need to adjust the clutch drive on the “ten”?

Car enthusiasts who already know how to adjust the clutch on a VAZ 2110 can promptly diagnose the condition of the unit. They are helped in this by having experience and knowledge; they do not need any consultations at a car service center. For example, no one will argue that replacing a clutch cable requires subsequent adjustments. Before you take a ruler to measure pedal travel, you need to pay attention to the behavior of the car:

- Jerks and impacts, as well as noise when turning on the speeds, indicate the need to adjust the drive.

- The start of the vehicle movement immediately after releasing the pedal indicates a lack of free play.

- In the case when the car does not move even with the clutch pedal fully released, the free play exceeds the norm.

How to check pedal travel?

Clear signs of trouble require a performance check of the clutch control pedal. The procedure is simple, does not require special skills and is described in detail in the instruction manual. So, before adjusting the clutch on a VAZ 2110, we perform the following steps:

- Place a ruler perpendicular to the outer edge of the pedal, resting it on the floor.

- Determine the distance from the floor to the outside of the pedal.

- The acceptable distance is considered to be 120-160 mm ; if the readings are outside the norms, adjustment of the drive is required.

How to get to a service center with a faulty clutch

1st method . If the clutch does not work at all, then getting to a car service center yourself in compliance with all safety requirements is difficult, but possible. To do this, you need to try to turn on the gear. This can be done by moving the gearshift lever to neutral, then releasing the gas and turning on the speed. If the lever gets stuck, lightly press the accelerator to release it.

2nd method . When a problem with the clutch requires an immediate solution, but it is not possible to fix the problem on the spot, this is how you can get to the service station. It is necessary to turn off the engine and engage first gear. Then turn the ignition key to start the engine. The car will initially move jerkily, since the first speed does not correspond to the engine speed at start-up, but then, when the speed levels out, the car will drive without jerking.

Before resorting to this method of delivering a car to a car service center, you need to warm up the engine well - otherwise, when you try to start, it will stall. Switching from first gear to second when the clutch is not working will also require compliance with certain rules. If you manage to get going in first gear, you need to pick up the optimal speed to engage second gear. Then release the accelerator pedal and set the gearshift lever to neutral, and then try to smoothly engage second speed.

We recommend

“How to improve brakes (vacuum brake from Priora)” Read more

At the end of our article we would like to pay attention to the prevention of problems with the car clutch. In order to encounter malfunctions of the mechanism in question less often and increase its service life, you need to adhere to the following recommendations:

- When operating a car, you must comply with the requirements of the car manufacturer.

- When starting to move, you must avoid slipping - move off smoothly and slowly.

- You need to constantly monitor the condition of the car’s clutch.

- To repair and maintain the clutch, only high-quality materials and components should be used. To perform such work, it is better to contact a specialized car service center.

Subject to operating rules, the clutch mechanism on domestic cars is usually replaced after 50,000–70,000 km. For foreign cars, this interval increases by another 30,000–40,000 km.

Traditional method: how to adjust the clutch on a VAZ 2110 without visiting a car service center?

Over the past few years, auto parts manufacturers have respected domestic car owners. By paying a little more, they have the opportunity to buy and install an imported clutch as a kit. But installing a new basket, disc and release bearing is only half the battle. It is necessary to correctly configure the drive of the transmission mechanism, for which it is enough to repeat a few simple transitions:

- Open the hood of the car (the engine is turned off) and find the junction of the cable and the clutch release fork.

- Using two open-end wrenches “13”, unscrew lock nut 1 (see photo), and use nut 2 to adjust the free play of the control pedal within 120-130 mm. The pedal stroke increases when nut 2 is unscrewed, and when it is tightened, it decreases.

- Press and release the pedal 3-5 times, then check the pedal stroke size with a ruler.

- If necessary, repeat the adjustment and then tighten the locknut.

The given procedure for setting up a backlash-free drive is overly simplified and is designed for car enthusiasts who do not have as their goal an in-depth knowledge of the car’s design.

What to do if clutch problems start

When operating a car, it is important to listen to the operation of its components and mechanisms. Identifying problems and malfunctions at an early stage will help avoid more serious breakdowns with expensive repairs.

Clutch repair may involve replacing the entire mechanism or its individual components and parts. The problem is that only experienced drivers who have the appropriate tools and equipment can perform high-quality clutch repairs on their own. Most car owners cannot cope with this task, so you should contact a car service center.

Clutch repair also has the disadvantage of high cost. In this case, owners of foreign cars will face especially large expenses.

Nevertheless, we want to provide a number of useful recommendations for solving clutch problems. Quite often the cause of failure of this mechanism is a malfunction of the driven disk. To perform repairs, you need to remove the driven disk and visually check it for damage.

It happens that the gearbox gears do not engage after the car has been idle for a long time. This problem is caused by “sticking” of the driven and pressure disks or the driven disk to the flywheel. If this malfunction occurs, you need to depress the clutch pedal several times and then try to engage the gear. If the problem persists, you can try another method. With the engine turned off, you need to depress the pedal, apply the parking brake and try to start the engine. If even after this procedure the clutch does not work, you need to contact a car service specialist.

The drive of the automobile clutch mechanism can be mechanical or hydraulic. The system may not turn off completely due to insufficient fluid level in the expansion tank or due to improper adjustment of the drive. The driver must periodically check the fluid level in the system and, if necessary, top it up to the required level.

A constant decrease in the brake fluid level in the clutch expansion tank indicates problems with the tightness of the hydraulic drive elements or a malfunction of the working cylinder (WCC). In addition, the breakdown may be caused by air in the hydraulic drive system. In this case, you need to remove air from the system by bleeding it.

If possible, it is worth inspecting the RCS for the presence of drips by driving the car onto an overpass. Such diagnostics are especially useful in winter, if you have not changed the fluid in the car’s hydraulic clutch system for a long time. Brake fluid is hygroscopic (the ability to absorb moisture), so if it is not changed for a long time, it can freeze in severe frost. Experts recommend changing fluids in the clutch drive and brake system every three years.

We recommend

“10 reasons why rear brakes stick” Read more

The clutch may not engage fully due to insufficient pedal travel. To fix this problem, you need to adjust the free play of the clutch pedal. If engine oil gets into the lining, the clutch disc will slip. To eliminate mechanism slippage caused by oiling or wear of the friction linings of the driven disk, you will need to replace or wash the worn parts. Oily linings are cleaned with solvents, but it is important to eliminate the cause of the oil leak.

The problem with incomplete clutch disengagement can be solved by taking the following measures:

- adjusting clutch drive settings;

- cleaning and lubricating splines;

- installing a new or adjusting an old driven pulley;

- installation of new friction linings.

As noted above, troubleshooting clutch faults requires special knowledge, skills and professional equipment. To ensure that all problems with the operation of this mechanism are solved, you should contact a car service specialist.

Reasoning about alternative regulation

Before adjusting the clutch on a VAZ 2110 in the traditional way, let’s think about how justified it is, and whether there is any point in using an alternative option. According to reviews from many owners of “ten” cars, and not only them, the clutch control pedal is quite high from the floor. The inconvenience that most drivers get used to is actually quite significant.

The driver gets tired during the trip, he wants to change gears less and less, each time lifting a heavy boot. This affects not only the speed of movement, but also the condition of the transmission. Experienced drivers assure: when the clutch pedal is released, it should be positioned so that it can be depressed without lifting the heel from the floor. It’s not without reason that on UAZs and Gazelles, where adjustment is impossible, experienced drivers place a piece of board under the mat.

The classic adjustment order indicates data that ensures the clutch disengages with a large margin. As a result, by fully depressing the pedal, the driver forces the bearing to bend the diaphragm spring much more than is technically necessary. As a result, it loses its characteristic properties, and at critical moments it simply breaks. And it doesn’t matter that you chose a branded clutch kit - everything is subject to the laws of physics.

Method for alternative clutch drive tuning

Experienced car enthusiasts prefer to make adjustments individually for each set of coupling parts. The event does not require an assistant or special equipment:

- Start the engine, depress the clutch and engage reverse gear. On almost all VAZ models it does not have a synchronizer, so the disks are completely disconnected.

- Slowly release the pedal and simultaneously engage and disengage reverse gear.

- The moment the speed is switched on is manifested by vibration on the shift knob. If the setting was made according to the official factory instructions, then the start of activation will correspond to a distance of the pedal from the floor of 75-100 mm.

- Set the cable length so that the “grasping” moment corresponds to 20 mm from the floor to the top edge of the pedal.

After we adjusted the clutch on a VAZ 2110 in this way, the clutch pedal in the initial position is much lower than the brake pedal. This allows you to instantly switch the toe of the boot without raising your foot to the handlebars. Early activation greatly simplifies the process of driving a car; gears are engaged smoothly and without jerking.

Eventually

In conclusion, it should be noted that there are some “homemade” ones who specifically move the release bearing away from the basket, explaining their actions by the fact that in this way they will be able to extend its service life. However, they will have to be disappointed - the bearing is unlikely to become more durable, but the petals of the diaphragm spring will gradually be milled by the untwisted bearing race. And, please note, we are not discussing the discomfort from increased pedal travel, which can result in much greater expenses than purchasing clutch elements.

Hello, yesterday I noticed that the clutch pedal had moved closer to the floor (more precisely, it began to operate in the floor itself). And the gears began to turn on and off with some effort (or biting), it was always low all the time, but yesterday I noticed some inconvenience in driving. Tell me what is the reason and what to do?

The VAZ 2107 clutch is designed to connect the engine crankshaft and the gearbox input shaft with the possibility of briefly stopping the transmission of torque. The reasons for its failure can be very diverse. However, all of them can be easily diagnosed and eliminated on their own.

Clutch mechanism of VAZ 2107

The VAZ 2107 clutch is a rather complex mechanism consisting of several dozen elements. The reasons for its malfunction can be very different. However, they can all be divided into two groups:

- Defects in the clutch mechanism itself. These include malfunctions of the driven part of the clutch, pressure device, basket, flywheel, and clutch fork.

- Defects in the hydraulic drive of the clutch mechanism. They can be caused by leakage of the working fluid, the formation of an air lock in it, as well as malfunctions of the main or working cylinders (MCC and RCC) and the pedal mechanism.

The clutch, like any other car part, has a limited service life. First of all, it depends on the skill of the driver, and therefore is not regulated by the manufacturer. To increase the service life of the clutch, it is necessary to adjust it in time, monitor the level of working fluid, avoid off-road driving, and learn the skills of using the clutch correctly.

It must be remembered that in addition, the clutch is a safety device that protects the transmission from serious damage when the rear wheels are blocked by various obstacles. The car is stuck in a quagmire, the drive wheels are stuck, the engine power is enough to turn the stuck tires. In this case, the clutch will begin to slip, protecting the gearbox, cardan and rear axle from damage. Yes, the driven disc linings will burn out. Yes, the clutch will overheat, which can cause the steel flats to warp or weaken the spring plates. But more expensive units will be protected from breakdowns.

Classic VAZ models have a dry, permanently closed single-plate clutch . It includes two main elements:

- Leading part. It consists of a driven disk, the splined part of which transmits rotation to the gearbox due to friction between the friction linings and the surfaces of the flywheel and pressure plate.

- Non-removable drive unit (basket). The basket is attached to the flywheel and consists of a pressure plate and a diaphragm pressure spring.

What is a clutch and how does it work?

The clutch mechanism provides the ability to enable/disable the transmission of rotational force from the motor to the transmission. This system plays a vital role in changing gears, braking and stopping the car. The clutch ensures smooth connection and interaction of the friction discs, which are located on the shafts of the engine and gearbox.

A properly adjusted clutch mechanism ensures that the vehicle starts moving smoothly. When a car with the engine running is standing still, the motor shaft rotates at high speed, and the transmission shaft remains stationary. For a smooth start to the movement of the car, it is necessary that the shafts of the engine and gearbox smoothly rub against each other and support an increase in the number of revolutions.

If the connection of the motor and transmission shafts occurs very sharply, then the gearbox shaft, which is in a static position, will jam the power unit shaft and the engine will stall (this situation is often encountered by novice drivers who abruptly release the clutch in a car with a manual transmission). In addition, this situation can lead to breakdowns of the clutch mechanism itself.

To prevent problems with the clutch, it will be useful for the driver to become familiar with the structure and operating principle of this mechanism. The main elements of its design are the driven and driven disks, the on/off system and the push drive.

The torque of the motor flywheel is transmitted to the drive shaft, which transmits rotation to the gearbox shaft. This is ensured by friction forces that arise due to the pressure drive. Tight adhesion of the drive and driven disks is a necessary condition for vehicle movement.

An equally important moment is disengaging the clutch. This process involves a pressure plate (clutch basket), which has built-in springs connected to a pressure base. The release bearing acts on the springs during clutch engagement/disengagement. The pressure plate is located in the cast iron crankcase of the motor block.

We recommend

“Clutch pedal vibration when pressed: causes of malfunction and methods for eliminating it” More details

The elements of the drive structure also include a flywheel, rigidly connected to the pressure plate with six bolts. Between the pressure plane and the flywheel is the clutch driven disc. The rotation of the pressure plate is ensured by a flywheel. The list of elements of the driven part of the clutch mechanism includes such parts as the driven disk, hub and gearbox drive shaft.

On two planes of the driven disk there are friction linings, which are made from a special material that includes asbestos and metal and has good friction characteristics. The driven disc itself is connected to the clutch hub using rivets or special springs. Friction springs are part of a rotation vibration damping mechanism called a damper.

Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing a VAZ 2107 clutch is a rather labor-intensive and expensive process. Therefore, before replacing, you should consider adjusting the mechanism.

Clutch replacement

To install a new clutch, you will need an inspection hole, overpass or lift. It is important to detect in time the signs indicating the need to replace the clutch (it is impossible to replace it on the road), and take the car to a garage or car service center. Driving with a faulty clutch is very dangerous - you can get into an accident when crossing a railway crossing or a main road.

The entire VAZ 2107 clutch is replaced, so auto shops sell a kit consisting of a driven disc, a basket and a release bearing. You should consider replacing the clutch in the following cases:

- the car climbs heavily uphill when the accelerator pedal is pressed all the way down, and you can smell a burning smell - these are signs of slipping of the driven part of the clutch;

- when the clutch is disengaged, noises appear in the area of the flywheel housing - this indicates a malfunction of the release bearing;

- when starting the car, it is difficult to engage first gear (the gearbox “growls”) - this is a sign that the clutch is not completely disengaged (the clutch is moving);

- when accelerating, the car begins to twitch, rattling sounds are heard - the reason for this is usually broken damper springs or loose sockets for them on the driven disk, deformation of segments or loose rivets on the hub.

Any noise, vibration, or whistle in the clutch area requires more detailed diagnostics and diagnosis.

Clutch adjustment

If the clutch pedal becomes too soft, falls down, and does not return to its original position, then most likely air has entered the system or the hydraulic drive adjustments have been disrupted. Clutch slipping after prolonged use usually indicates a failure of the clutch. It will probably have to be changed.

If the clutch drives, that is, shifts gears with difficulty, in about half of the cases the reason is a discrepancy with the required values:

- play between the rod and the piston in the working cylinder;

- clearance between the release bearing and the fifth basket;

- free and working travel of the foot pedal.

How to self-diagnose problems

During active use of a car, its clutch constantly works in different modes, and therefore, problems with this mechanism quickly manifest themselves and lead to changes in the nature of the car’s movement.

Considering various malfunctions of a car clutch, we can distinguish two main groups of problems with this mechanism. The first includes faults that appear when the clutch is disengaged, and the second includes difficulties with turning it on. To eliminate the causes of clutch problems, you must first determine which group the malfunction occurs in.

It is worth noting that in most cases even an inexperienced driver can detect irregularities in the operation of the mechanism in question. So, in order to diagnose incomplete clutch disengagement, you need to try to engage first gear at low engine speeds with the pedal fully depressed. If no extraneous sounds or vibrations appear, and the gear engages easily, then your car’s clutch does not have any problems in this group of faults.

The presence of malfunctions from the group of incomplete engagement of the clutch mechanism may be indicated by a loss of power while the car is moving (especially on inclines), a constant specific smell of “burnt” clutch disc linings, as well as an increase in engine speed without increasing the speed of the car when pressing the gas pedal.

To more accurately diagnose the problem of incomplete clutch engagement, you can conduct a simple experiment. You must first warm up the engine and, if possible, drive the car for about 15 minutes (this is necessary for the gearbox to warm up as well). After this, you need to stop the car, set the gear to neutral and apply the parking brake or depress the brake pedal. Then, pressing the accelerator, you need to keep the engine speed at 1500, squeeze the clutch and engage first gear, smoothly releasing the clutch pedal. If the engine does not stall afterwards (or stalls after some time), then there is a problem with the clutch engaging and the car needs to be repaired.

Diagnosis of clutch faults VAZ 2107

External manifestations of a VAZ 2107 clutch malfunction are:

- difficulties when changing gears;

- slippage of the driven part;

- vibration;

- pressure bearing whistling;

- tight pedal assembly;

- the pedal does not return to its original position after pressing;

- other signs.

Clutch slipping

You can check whether the clutch is slipping as follows. The third or fourth speed is turned on and the handbrake is pulled. If the engine hums, the car does not move, and there is a burning smell in the cabin, it means that the driven part of the clutch is slipping. This can happen for several reasons.

- The pedal has little play. If a problem is discovered after replacing the clutch, the cause is incorrect adjustment of the hydraulic drive. Lack of clearance between the pressure bearing and the fifth basket results in the driven disc not being clamped properly. It is necessary to adjust the length of the pusher, setting the play to 4–5 mm.

- When starting from a stop or while driving on an uphill slope, the clutch burns, that is, acrid smoke begins to come from below. This indicates wear or burning of the driven disk linings, made of friction-resistant composite material. In this case, the clutch must be replaced.

Clutch leads

If the clutch is moving, it becomes very difficult to engage first gear, and if the clutch is disengaged, the car does not stop and continues to move. When the pedal is pressed, the driven disk remains clamped, that is, it is not disconnected from the flywheel and pressure disk. This situation may be due to the following points.

- There is too much clearance between the pressure bearing and the heel of the pressure plate. As a result, the clutch does not disengage completely. The length of the RCS rod should be reduced so that the distance between the bearing and the fifth becomes 4–5 mm.

- Mechanical damage to the driven disc due to overheating of the clutch in difficult vehicle operating conditions. This leads to the appearance of fine shaking in the transmission when the end runout exceeds the permissible 0.5 mm. In this case, it is better to replace the clutch with a new one.

- Pulling out the rivets on the friction linings and, as a result, increasing the thickness of the driven disk. The driven disk needs to be replaced.

- Wear of internal splines on the driven disk hub. This can lead to jamming on the gearbox shaft splines. If wear is detected, lubricate the splined part with high-quality automotive lubricant LSC-15 or replace the parts with new ones.

Jerks when starting and changing gears

If the car starts to twitch when starting from a stop and changing gears, the reasons for this may be the following situations:

- The driven disk is jammed on the gearbox shaft splines.

- There is oil in the basket.

- The hydraulic drive is misaligned, the RCS piston is jammed.

- The friction linings are badly worn.

The most common causes of clutch problems

We noted earlier that most often clutch problems are caused by violations of the vehicle operating rules provided by the manufacturers. So, if a car is stuck on a snowy section of the road or in the sand off-road, drivers continue to press hard on the accelerator to get out of the trap. In addition, many car owners generally practice starting to drive with wheel slipping. Such actions significantly reduce the life of the clutch disc.

The clutch parts that most often fail include the release bearing. This part ensures smooth clutch engagement/disengagement. If the release bearing has “exceeded” its service life, then the operation of the clutch will be accompanied by a specific squeal, upon hearing which the faulty part should be urgently replaced.

Quite often, the cause of problems in clutch operation are malfunctions of the drive mechanism, expressed in jamming and defects of the cable, incorrect operation of the lever system, leakage of working fluid (for cars with a hydraulic clutch), etc. To take a closer look at all possible causes of clutch malfunction, let’s group them according to certain characteristics.

If the clutch does not disengage completely, it “leads”, the gears work poorly, and the reverse gear is engaged with a characteristic crash, the causes of the problems may be the following:

- Incorrectly set gap.

- Deformation or other defects of the driven disk.

- Worn diaphragm spring.

- Breakage, souring and other defects of the cable or lever transmission.

- Leakage of working fluid (for hydraulically driven mechanisms).

- Defects in the piston cuff of the working cylinder.

- Clutch pedal travel is too short.

- Insufficient lubrication of the clutch guide bushing.

- Jamming of the driven disk hub, which is located on the splines of the input shaft.

- Improper adjustment of the pressure plate levers.

When the clutch is not fully engaged, the car slips, accelerates poorly and has difficulty climbing hills, and there is a noticeable smell of “burnt” friction linings.

The causes of the clutch problems described above may be as follows:

- The driven disk of the mechanism is poorly worn.

- The diaphragm spring has lost its elasticity or is damaged.

- The permissible degree of wear on the working surface of the flywheel has been exceeded.

- The clutch cable is stuck.

- The pressure springs have weakened.

- The friction linings are oily.

- Clutch components are excessively worn.

- The compensation hole in the master cylinder is clogged or blocked by a swollen cuff.

We recommend

“Car clutch malfunctions: rating of breakdowns and causes of their occurrence” Read more

The causes of vibrations when turned on are:

- Defects in engine and gearbox mounts.

- Worn gearbox input shaft splines.

- Loss of elasticity of the diaphragm spring, increased wear of the pressure plate or flywheel.

- Warped clutch linings.

- Violation of the integrity of the rivets on the clutch disc linings.

- Loss of elasticity of the plate springs of the driven disk.

- Seizing of the driven disk hub on the splines of the input shaft.

In addition, the problem of vibration when engaging the clutch may be due to improper adjustment of the pressure plate. The same consequences result from a violation of the pedal free play setting, defects in the driven disk, as well as wear on its springs or damper mechanism.

Extraneous sounds when the clutch mechanism is disengaged can be caused by excessive wear or malfunction of the release bearing, defects in the diaphragm pins or the front bearing of the transmission input shaft.

Noise when the clutch is engaged is possible due to deformation or loss of elasticity of the damper springs or release fork (this part can also jump out of its seat), as well as a violation of the integrity of the plates connecting the pressure plate and the casing.

If the clutch pedal does not rise when the ignition is turned off, this may be due to a stuck release bearing or mechanism drive. The problem of squeaking, which is especially clearly heard when the clutch pedal is depressed with the engine turned off, is a consequence of dry running due to insufficient lubrication or severe wear of the pedal axle bushing.

Another common malfunction is that the clutch is disengaged only by sharply squeezing the pedal (smoothly pressing the pedal to the floor in this case does not lead to the clutch being engaged). The reasons for this clutch problem may be:

- Worn or dirty master cylinder mirrors.

- Worn master cylinder piston o-rings.

- Insufficient level of working fluid in the expansion tank.

- Depressurized connections of tubes with the working and main cylinders, accompanied by fluid leakage.

If the clutch operates jerkily, you need to check the driven disc hub and clutch mechanism for sticking. Other causes of this problem may include oily or worn friction linings, dirt in the drive mechanism, or loose rivets.

Clutch adjustment VAZ 2107

Clutch adjustment is a mandatory step after troubleshooting or replacement. When dismantling the gearbox, basket, or driven disk, the control rod is usually unscrewed, so after assembly, the adjustment must be done again. This is also necessary if during the operation of the car, for one reason or another, the clutch on/off mechanism is broken. It's quite easy to make the adjustment yourself. To do this, you will need an inspection hole, overpass or lift.

Tools and materials

- open-end wrenches for 8, 10, 13 and 17;

- measuring ruler or construction corner with divisions;

- pliers;

- Cobra pliers;

- water-repellent composition WD-40.

The clutch adjustment is carried out after bleeding the hydraulic drive.

Adjusting the pedal free play

The pedal free play should be from 0.5 to 2.0 mm. It is regulated from inside the car by changing the reach of the clutch pedal limiter.

The procedure for this is as follows

- Using one 17mm wrench, loosen the locknut by 2-3 turns, and with the other same wrench, rotating the head of the limiter, change its length.

Adjusting the free play of the fork rod

The free play of the fork rod is the gap between the release bearing and the fifth diaphragm spring of the pressure plate. Its adjustment is carried out on the inspection pit or lift as follows.

- To make it easier to control the free movement of the fork, use pliers to remove the ends of the return spring from the clutch fork and from the plate under the working cylinder mounting bolts.

Adjusting the fork rod

The threaded part of the rod is not protected from dirt and moisture, so the adjusting nut and locknut may not immediately unscrew. It is recommended that after cleaning the rod from dirt, apply WD-40 to the threaded part. You are then prompted to perform the following steps.

- Holding the adjusting nut with a 17 wrench, use a 13 wrench to loosen the lock nut by 2-3 turns.

After adjustment, it is recommended to check the operation of the clutch. To do this you need:

- start and warm up the engine to operating temperature;

- Depress the clutch pedal and engage first gear;

- turn off first gear and engage reverse.

A properly adjusted clutch should press out easily, without jamming. Speeds switch on without difficulty or noise. When driving, there should be no slipping of the driven disk.

Types of clutch

Clutch mechanisms in modern cars are divided into several types according to the following criteria:

- By drive type . The clutch can be controlled by mechanical, hydraulic, electrical or combination drive systems.

- According to the type of friction of the friction linings . The clutch can be dry or wet (the linings work in a special oil bath).

- According to the method of activation (permanently or non-permanently closed types of clutch).

- By number of slave disks. Clutches can be single-disc, double-disc or multi-disc (see photo).

- By the type of pressure springs and their location (several springs located along the periphery of the pressure disk, and with one diaphragm spring located in the center of the disk).

- By the number of threads transmitting torque (1 or 2 threads).

The simplest clutch design includes a mechanical drive. In such mechanisms, the force from the pedal pressed by the driver is transmitted to the clutch fork by various rods and cables. In hydraulic drive systems, there is a piston that transmits force through the working fluid. These types of clutches greatly simplify driving for the driver and are most often installed on heavy-duty vehicles.

The design of the hydraulic clutch drive ensures constant full pedal travel (the return spring is responsible for returning the pedal to its original position), but changes the magnitude of the working stroke. This ensures compensation for the reduction in thickness of the driven disc due to wear. When the clutch disc is worn, the full travel of the pedal does not change, but its working stroke increases, so the clutch engagement point gradually shifts towards the end of the reverse stroke.

For mechanisms with a mechanical (cable) drive, an increase in the full pedal stroke is observed under the influence of wear on the driven disk. In other words, the pedal gradually rises. At the same time, its working stroke increases. Adjustment of the pedal free play is carried out by changing the length of the cable. The normal free play of a mechanically driven pedal is about 30–40 mm.

Depending on the design features, the clutch in a car can be electromagnetic, frictional or hydraulic. With a friction mechanism, rotation from the motor shaft is transmitted due to friction forces. An electromagnetic clutch transmits torque using magnetic fields. In hydraulic mechanisms, the clutch of the engine and the gearbox is carried out with the participation of a liquid flow.

When the electromagnetic clutch is turned off, the driven and driving elements are open. When the clutch is engaged, the solenoid creates a constant magnetic field, which ensures the connection of the motor flywheel with the gearbox shaft. This mechanism is used quite rarely and is installed on small-class cars with manual control.

In an electromagnetic clutch, the space between the drive and driven discs is filled with a special ferromagnetic powder, which does not interfere with the individual rotation of the shafts. When the clutch is engaged, due to a constant magnetic field, the powder hardens and ensures the transmission of torque.

To equip trucks, sports cars and other vehicles operating under high loads, ceramic clutches are used, the discs of which have a high coefficient of friction. This clutch grabs quite sharply, so it cannot be used in standard cars.

Most often, modern cars are equipped with a friction clutch (single-disc, double-disc or multi-disc).

Depending on the environment in which the friction linings operate, the car’s clutch can be wet or dry. In the second case, the disks operate under dry friction conditions. A wet clutch is based on the transmission of torque between discs that are in an oil bath (this type of mechanism is mainly installed on motorcycles with a transverse engine).

Motorcycle engines have a common oil sump with the gearbox, so the clutch elements here are combined with the transmission and engine starting system and are lubricated with engine oil. Wet clutches are not used to equip modern cars.

We recommend

“The design of the clutch cylinder: a little theory for successful practice” Read more

To equip vehicles with powerful power plants, double-disc or multi-disc clutch mechanisms are used. Such systems, with normal dimensions, can transmit higher rotational forces and have an increased service life. In multi-disc clutches, a special spacer is provided between the discs to increase the friction surface.

On heavy trucks, automakers install clutch mechanisms with a pneumatic drive booster. This solution makes it possible to reduce the force that the driver needs to apply to depress the clutch pedal.