Operating principle

To determine the cause of the problem and take action to troubleshoot the EPHH, you need to know about the principle of its operation.

- The economizer is equipped with output and input circuits.

- The input circuits are a limit switch and a wire that connects to the switch.

- The throttle (throttle) limit switch tells the economizer whether the gas pedal is depressed or not at that particular moment.

- If the pedal is not depressed, the limit switch closes to ground.

- As soon as the gas pedal is pressed by the driver, the contact is switched off.

- The wire that connects the switch and the economizer reports the number of pulses to the ignition coil. In fact, due to this, the economizer is able to find out about the actual current speed of the power unit.

- The EPHH has only one output circuit - the XX solenoid valve of the carburetor system (XX - idle speed). The economizer can turn this valve on and off.

- Fuel economy is ensured by closing the XX fuel jet at high engine speeds.

- If the gas pedal is not depressed, the throttle limit switch closes to ground, the speed is less than 2.1 thousand per minute, then the economizer opens the XX solenoid valve.

- When the gas pedal is depressed, the limit switch opens, leaving the valve open anyway. The valve closes only when the engine speed exceeds 2.1 thousand per minute.

- The valve is in the closed position until the speed drops below 1.9 thousand per minute.

Actually, this is all you need to know about the operation of such an element as EPHH.

Practice and research show that the use of an economizer allows you to save about 5 percent of engine consumption.

Restoring stable idle

Restoring a stable idle shouldn't be too difficult. Troubleshooting procedure;

- Using a key set to “17”, unscrew the pneumatic valve from the carburetor.

- The valve is disassembled, washed well with kerosene or pure gasoline and blown out with compressed air.

- We screw it into place and check its functionality.

If, however, the cause of the unstable idle speed has not been eliminated, you need to check the power supply control circuit. If the power supply circuit is broken, the carburetor pneumatic valve is constantly in the closed position. This results in the engine not idling. Repairing the open circuit will solve this problem without much effort.

Malfunctions associated with the electro-pneumatic valve are extremely rare, but if this happens, it should be replaced.

Vacuum from the intake manifold is supplied through the pneumatic valve to the economizer diaphragm, due to which the economizer needle valve opens

When the pneumatic valve is turned off, the economizer cavity above the diaphragm communicates with the atmosphere - the needle valve closes, interrupting the supply of the fuel mixture through the idle channel to the engine.

Control unit 25.3761 turns off the pneumatic valve at an engine speed of 1600 rpm and turns it on again when the speed drops to 1200 rpm.

The microswitch supplies voltage to the air valve, bypassing the control unit, when the throttle valve is open.

Diagram of the forced idle economizer system (EFS): 1 - solenoid pneumatic valve; 2 — intake manifold; 3 — economizer needle; 4 — economizer body; 5 — adjusting screw for the amount of mixture; 6 - microswitch; 7 — mounting block; 8 — ignition switch; 9 — ignition coil; 10 - control unit.

1. Connect a voltmeter or test lamp to the valve power wires.

If there is no voltage on them when the ignition is turned on, we check the control unit (Checking the EPHH VAZ-2107 unit).

2. To further check the valve, disconnect the connecting hoses from it.

3. We put a suitable rubber hose on fitting “1” (central) and create a vacuum in it with our mouth. In this case, close the fitting “2” (side) with your finger. The valve must be sealed.

Turning on the ignition, apply voltage to the valve output. The valve of fitting “1” should open, making a characteristic click, and close again when the voltage is removed.

4. We replace the faulty electro-pneumatic valve. To do this, use an “8” wrench to unscrew the valve mounting nut.

We connect the hose from the carburetor economizer to the side fitting, and the hose from the intake manifold to the central one.

Symptoms of a problem

There are several main signs indicating failure of the EPHH:

- The engine regularly stalls at idle;

- Detonation occurs in the engine when the ignition is turned off;

- The engine stalls when coasting braking is performed.

You can check whether the EPHH and its control unit are working correctly with your own hands. To check the valve, you should monitor its activation in various operating modes. Correct operation is determined by ear or using a voltmeter.

Valve check

There are three main steps to checking the functionality of the solenoid valve.

Verification method

Your actions

Basic operating mode of EPHH

- Start the engine and begin to gradually increase the speed of the power unit;

- Once you cross the 2100 rpm mark, the valve should turn off. This will be heard as a click;

- Now increase the speed to 4000 rpm. In this case, the valve must remain closed;

- Smoothly reduce the speed again, reaching below 1900 rpm. At this moment, the working valve clicks again, which indicates that it is turned on

Engine braking mode

- Disconnect the chip from the damper position limit switch and connect it to ground;

- This action will trick the economizer into telling it that the gas pedal has been released;

- Start the engine and raise the speed above 4000 units per minute;

- Gradually begin to reduce speed;

- When you reach 1900 rpm, the valve should not turn on;

- The limit switch is closed to ground, speeds above idle trigger the engine braking mode. The economizer should not turn on the valve.

Fuel cut-off when ignition is turned off

- Warm up the engine to 90 degrees and turn off the ignition;

- In this case, the engine should stall immediately, not vibrate or rattle;

- If vibrations occur, this indicates that the solenoid valve is not closing the idle jet;

- As a result, gasoline continues to flow into the heated power unit

In addition to the solenoid valve itself, you should also definitely check the EPHH control unit.

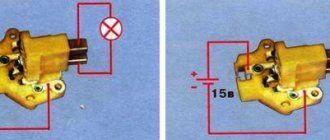

Plus and minus

Checking the control unit

To check the control unit of the solenoid valve of the carburetor VAZ 2109 you will need a wire. The length of the wire should be such that it is sufficient to connect the valve to the positive terminal of the battery. Plus, you will need a standard voltage control light.

Your steps when checking the control unit will look like this.

- Disconnect the power wire from the valve without interfering with the operation of the carburetor itself. After this, connect the valve via the prepared wire to the positive terminal of the battery.

- The supply wire of the solenoid valve, which you disconnected in the previous step, must be connected to the positive terminal of the control lamp. The minus connects to the mass.

- Turn on the engine and let it idle for a while. The crankshaft should rotate at a speed within 850-900 rpm. The control lamp should light up.

- Begin to gradually increase the speed, reaching 2100 units per minute. If the control unit is working properly, when this level is reached, the light will go out. Reducing the speed again to 1900 units per minute, the lamp should light up.

Useful diagram

If a malfunction was discovered during the check of the valve and its control unit, you will need to replace the corresponding failed components of the carburetor power system of the VAZ 2109.

EPHH is an important component of the car, which requires constant monitoring by the car owner.

Design and operating principle of solenoid valve

For the production of solenoid valves, materials are used that meet the requirements of GOST and international standards. The solenoid valve consists of several main elements:

How does a solenoid valve work?

The operating principle of the solenoid valve is based on the operation of the control element - the electromagnetic coil. In the absence of direct or alternating current under mechanical pressure, the springs and membrane (piston) of the valve are located in the seat of the device. When electrical voltage of varying power is applied to the solenoid terminals, the core is drawn into the coil, ensuring the opening or closing of the duct opening. De-energizing the solenoid causes the valves to close. The design features of the solenoid valve may vary depending on its type.

Types of Solenoid Valves

Solenoid valves are divided into several categories.

By type of working position there are:

- Normally open valves. By default, the valve element is in the open position and does not interfere with the flow.

- Normally closed valves. The absence of voltage on the coil is characterized by the closed position of the gate.

- Bistable valves. Capable of switching to open or closed position under the influence of an electrical impulse.

Based on their operating principle, solenoid valves are divided into:

- Direct acting valve. the position of the gate component changes under the influence of the movement of the core when electrical voltage is applied.

- Indirect acting valve. The influence of the energy of the working environment leads to the opening and closing of the conditional passage. It is controlled remotely by a pilot valve, which is activated when electrical current is applied to the coil.

- Combined action valve. The shutter is adjusted according to

the principle of raising the membrane of the solenoid valve. By type of connection to the pipeline:

By type of sealing membrane:

- Membrane FKM (fluoride rubber). Standard seal, suitable for most non-aggressive media.

NBR membrane (nitrile butadiene rubber). Used in petroleum products: gasoline, oils, kerosene, diesel fuel.

EPDM membrane (ethylene-propylene rubber). It is characterized by increased resistance to temperatures, works in the environment of chemical solutions and compounds: alkalis, alcohols, glycols, ketones, etc.

Installation and operation rules

Any installation work on the valve is carried out in the absence of a working medium in the system and in the absence of power to the electrical circuit. Before starting work, the pipeline should be cleared of mechanical particles and suspensions.

How to connect an electromagnetic (solenoid) valve. The solenoid valves in the system are connected in a horizontal position, with the coil facing up.

- For proper operation of the device, the direction of movement of the medium must correspond to the indicating arrow on the housing.

Installation of the solenoid valve

is carried out in a place accessible for subsequent repairs or maintenance. It is prohibited to install the valve in places with high rates of condensation or vibration, areas with possible icing of the pipe, near leaks and gusts.

Installing additional strainers of a suitable size will protect the valve from contamination and, as a result, a decrease in its hydraulic characteristics.

Advantages of solenoid valves

- Automatic type of operation

High performance

Remote control capability

Compactness (small size and weight)

Long service life

Easy installation and maintenance

Causes of breakdowns and methods of elimination

Correct operation and compliance with the technical parameters specified in the product data sheet will ensure reliable and long-term operation of the device. In some cases, premature

Solenoid valve malfunctions are possible for several reasons.

- A decrease in the tightness of the product can be caused by mechanical particles entering the device seat. It is recommended to dismantle and clean the device and then install a strainer in the system up to the valve.

Failure of the induction coil may be caused by incorrect voltage supplied to the terminals or by exceeding the temperature and pressure limits inside the pipeline. The device should be dismantled and the coil replaced. Moisture on the coil may cause a short circuit and damage the device.

Incomplete opening/closing of the valve may result from contamination of the control hole, defects in the membrane or gasket, residual voltage on the solenoid, etc.

Solenoid valve repair

must be carried out by a qualified specialist licensed to work with electrical networks. The production of solenoid valves is carried out at specialized pipe fittings factories located in almost every country in Europe. One of the world's leading manufacturers of solenoid valves is SMART HYDRODYNAMIC SYSTEMS. The cost of an electromagnetic valve depends on its functions, design type, thread diameter and the manufacturer of the electromagnetic (solenoid) valves. To determine the required type of device, you can consult with specialists or watch a video of the solenoid valve.

Solenoid valves have found application in various industries, where they are used to regulate the flow of certain types of substances. The design of such mechanisms has a different structure, which depends on the specific type of product.

When purchasing Danfoss solenoid valves, you should definitely consult with a specialist who will clarify all its main parameters and scope of application. This type of device has proven itself very well, which allows it to be used under different operating conditions.

Principle of operation and symptoms of failure of control equipment

The immediate task of the electromagnetic valve installed in the carburetor of the VAZ 2109 engine is to stop the fuel supply in “inertial” modes:

- engine braking;

- movement downhill;

- gear shift.

The electromagnetic switch is an integral element of the forced idle economizer and executes commands from the control electronics. The EPHH device is programmed according to the following algorithm:

- when the crankshaft rotation speed is more than 2,100 rpm and the gas pedal is released, the actuator is turned off, the needle closes the holes, fuel is not supplied;

- upon reaching 1,900 rpm, the device turns on, the needle retracts and the fuel begins to move through the channels.

Checking and repairing the EPH system of carburetor 2108, 21081, 21083 Solex

The forced idle economizer system of the carburetor 2108, 21081, 21083 Solex and its modifications is designed to forcibly shut off the fuel supply to the engine cylinders through the carburetor idle system during engine braking (coasting with the gear engaged and the gas pedal fully released).

It also prevents fuel from entering the engine after it is stopped, thereby preventing it from operating with the ignition off (glow ignition).

Signs of malfunction of the EPH system of carburetors 2108, 21081, 21083 Solex

— No or unstable idle. The engine stalls or runs rough

— The engine stalls in engine braking mode (when coasting with the gear engaged and the gas pedal fully released).

— The engine stalls when the gas is suddenly released at speeds above average (2000 and above) .

— After stopping and turning off the ignition, several flashes occur in the cylinders (dieseling).

Causes of malfunction of the EPH system

— The solenoid valve is faulty. — The solenoid valve control unit is faulty. — The contact of the fuel mixture “amount” screw is oxidized, dirty or damaged. — The connecting wires are damaged or their tips are oxidized. — The connectors of the connecting blocks have come off.

Tools for repair

— Open-end wrench 13 mm. — A piece of wire 0.5 meters. — Tachometer. — Voltmeter. — Ohmmeter.

Or one multimeter or autotester that can work in all these modes.

Checking and repairing the Solex carburetor solenoid valve

1. Remove the wire end from the solenoid valve.

2. Turn on the ignition.

3. Put the wire end back on.

4. You should hear a click when the valve operates.

If there is no click, then use a piece of wire to connect the positive terminal of the battery and the terminal of the solenoid valve. There is a click - the valve is working, but the control unit or connecting wires are faulty. There is no click - the valve itself is faulty and must be replaced.

This is the solenoid valve of the 21083 Solex carburetor. There is a marking on the jet 41.

EMK 21083

And this is the solenoid valve of the carburetor 2108, 21081 Solex. It has a slightly different shape and is already marked on the fuel nozzle 42.

EMK 2108

Both valves are interchangeable.

In addition, you can check the serviceability of the solenoid valve and the correct installation by removing the wire tip from the valve outlet with the engine idling. The engine should stall. If it does not stall, then the needle may be stuck in the valve or it may not be fully tightened.

We unscrew the valve, remove the fuel nozzle from it, and check the mobility of its needle. We wrap the valve back by hand, do not put the wire on it yet, start the engine and then continue to wrap it with an open-end wrench. Turn it in slowly until the engine starts to stall. Next, we put a wire on the output of the solenoid valve - the engine should start normally, and stall after disconnecting the wire. For more details, see “Features of installing the Solex solenoid valve.”

It may be necessary to slightly rotate the valve with a key back and forth (with the wire end on) in order to achieve more stable engine operation.

There is no need to repair the valve if it malfunctions. We replace the faulty valve with a new one.

Checking and repairing the control unit of the EPH system of the Solex carburetor

1. Take a voltmeter and connect one of its terminals to the terminal of the solenoid valve, and the other terminal to the “ground” of the car (the “ground” can be a body part, a metal part of the engine, or the “minus” of the battery).

2. Connect the tachometer.

3. Start the engine and look at the voltmeter.

4. At idle, the voltage must be at least 10 V (equal to the on-board voltage).

5. We increase the engine speed to 4000 rpm and sharply reset.

On-site diagnostics of the carburetor solenoid valve of a VAZ 2109 engine

It is possible to determine the performance of EPHH components as a whole directly on the carburetor. The procedure is as follows:

- remove the standard terminal from the valve;

- turn on the ignition;

- reconnect the terminal.

valve When connected, a characteristic click should be heard, indicating that the needle is retracted and the economizer as a whole is working.

The absence of sounds in the area of the VAZ 2109 carburetor indicates either a failure of the solenoid valve or a defective control unit. A faulty sensor is identified “locally” as follows:

- a piece of wire is prepared to connect the element being diagnosed directly to the “plus” of the battery;

- the standard power wire of the electromagnetic switch is disconnected;

- the ignition is turned on;

- a previously prepared conductor that is already connected to the positive pole of the battery is connected.

If a click is heard during the connection process, the valve is working properly, the problem is hidden in the EPH control system. An alternative method for diagnosing the performance of the control needle does not require available tools. With the engine running, it is enough to remove the tip of the standard wire from the element terminal and observe the reaction of the engine. The engine has stalled - the element being diagnosed is absolutely serviceable.

Independent examination of the valve condition

A detailed check of the functioning of the needle is possible only after dismantling the element under test. You must first remove the air filter and the filter element housing itself. The switch is unscrewed with a regular open-end wrench 13, carefully removed from its seat, and the analog element that dispenses the amount of fuel is removed.

The range of actions for a full diagnosis is as follows:

- pre-prepared conductors are connected to the battery terminals;

- “plus” is connected to the terminal, and “minus” is connected to the body of the part;

- The device reacts after voltage is applied.

dampers The shut-off needle is unprecedentedly retracted into the device body in the presence of a potential difference and instantly returns to its original position - the device is subject to further operation.

By turning on the ignition and closing the VAZ 2109 solenoid valve to the carburetor (body to body), with a known working EPHH control system, it is easy to assess the suitability of the locking element. As a result of contact with the “ground”, the needle should go inside the body with a characteristic click. Experienced owners test a newly purchased switch in this way.

- before screwing the device back in, the fuel nozzle should be washed/blown out;

- if the precision holes are heavily soiled, it is necessary to clean them with a fishing line or a soft wood needle;

- a loose valve may make it impossible to start the engine when the crankshaft is rotating;

- When tightening the element, you should not apply great forces, leading to deformation of the actuators of the part.

Briefly about the main thing

The solenoid valve stops fuel supply when the accelerator pedal is released and the crankshaft speed is more than 2,100 rpm, and resumes fuel supply at a frequency of less than 1,900 rpm under the same conditions. A faulty switch will prevent the engine from starting or will deliberately stop it from running.

There are several ways to check the serviceability of the solenoid valve on the carburetor of a VAZ 2109 car:

- connect standard or bypass power to the element output - a click should sound;

- remove the standard wire from the device with the engine running - the engine will stall;

- dismantle the sensor, connect it to the standard circuit and lean it against the carburetor - the needle will retract with a characteristic click;

- Connect the dismantled sensor to the battery: the needle should retract freely when voltage is applied and extend when there is no voltage.

Application of two-way valves in automotive systems

Since numerous vehicle systems constantly require shutting off, redirecting and mixing various flows of liquids or gases, the use of various bypass devices, such as valves, is required. The principles of their operation are based on different drives: pneumatic,

Setting up the carburetor of a 4-stroke scooter

Tuning the carburetor of a 4-stroke scooter is, of course, not rolling back the injector using broadband lambda, but it also requires a competent approach and knowledge. For stable operation and efficiency, Chinese manufacturers have developed and implemented several design additions. Before you get started

Carburetor DAAZ-4178 - installation and main causes of malfunctions

The Dimitrovgrad Automotive Component Plant produces DAAZ-4178 carburetors for UAZ vehicles, which can be used instead of the standard K-151V. The manufacturer guarantees an increase in dynamics and a reduction in fuel consumption to the level of 11 liters per 100 km in mixed mode, which is comparable to the fuel consumption of a GAZ

Selection of jets on a Solex 21083 carburetor

The Solex 21083 carburetor model with jets that affect the properties of the fuel-air mixture can be modified to suit any engine size. To do this, it is enough to select jets, which is quite possible for an experienced car enthusiast. Solex 21083, subject to proper improvement, is quite

What’s easier: to rack your brains or figure out how the carburetor works in a Lada?

To an uninitiated user, it may seem that the VAZ 2109 carburetor is complicated, so not many people decide to adjust it themselves.

Why did the Solex break down?

A carburetor is the main element of a car's fuel system. It is designed to mix air with fuel in the required proportions and form a fuel mixture supplied to the combustion chambers of the engine.

Device

The VAZ 2109 carburetor consists of two main elements - the body and the cover. All parts are mainly located in the housing (pump, jets, float, etc.). Also, the power system, which may be associated with repairs, includes: candles, EPHH, and so on.

When the pump pumps fuel from the tank, it first enters the carburetor float chamber block. This chamber is also called the first or primary. It serves to maintain an optimal level of gasoline at which the carburetor can operate normally and maintain stable speed. At the entrance to the chamber, there is a special fitting through which fuel passes. Its quantity is controlled by the valve, as well as several floats. When you lightly press the gas pedal, the amount of gasoline entering the chamber, and accordingly its pressure, decreases sharply. In order for the flammable mixture to enter the chamber normally, at low pressure, the valve rises higher, clearing the way. This process is continuous and runs as long as the engine. The valve structure is closely connected to the float. This control scheme eliminates the chance of spark plug overflow.

When you sharply press the gas pedal, a large amount of fuel enters the primary chamber block. In order to protect the candles, there is a secondary chamber. It opens when the engine speed is high. The first chamber, with the accelerated movement of fuel, pours it into the second, and ensures a uniform, enriched mixture when it enters the cylinder, thereby preventing pedal failure.

For normal operation of the VAZ 2109 engine, simply gasoline is not enough. The carburetor must also receive air. It enters through the valve into the float chamber block, where it is mixed with fuel and forms a flammable mixture.

In addition to when the VAZ 2109 car is in motion, it can also be stationary, but with the engine running. Here a device such as idle speed is already triggered. It is regulated separately, supplying fuel through a solenoid valve to the float chamber. The idle control circuit includes an electronic device - an economizer. It activates the solenoid valve at speeds below 1700 rpm and deactivates when the gas pedal is pressed.

It is very important to know that food does not always pass through an economizer. Sometimes, the idle circuit bypasses this device, turning on the solenoid valve directly from the ignition.

Also, the carburetor has such a device as: the EPHH control unit. It serves to reduce the amount of exhaust gases and reduce fuel consumption. The EPHH control unit, on a VAZ 2109 car, is mounted separately from the entire power system. For example, when a car is moving downhill while in gear, the gas pedal is completely released. At the same time, the throttle valve closes and the EPHH control unit is activated, raising the solenoid valve.

Video - Installation of the EPHH system

An increase in fuel consumption can be due to many factors, including improper operation of the EMR. If the valve spring is weakened or broken, the economizer valve will be constantly open, re-enriching the air-fuel mixture. When the gas pedal is fully pressed, this increases engine power, but in other modes, on the contrary, it leads to a drop in power. Because of this, the driver is forced to press harder on the gas, which further increases fuel consumption. If the EMR diaphragm has lost its seal or the cap is not tightened properly, gasoline will enter the intake manifold below the throttle valve and also leak out. The latter is especially dangerous because it can cause fuel to ignite.

Operation and repair

The VAZ 2109 carburetor, like all other parts, tends to break. Typically, a breakdown involves the failure of any spare part. In such cases, repair usually helps.

The first thing that can break is the accelerator pump. Its purpose is to enrich the fuel mixture, regardless of the air supply, when the throttle valves are opened. If, when you sharply press the gas pedal, the car jerks, it means that there is either not enough fuel, and significant gaps occur in the supply, or, on the contrary, there is too much of it, and it overflows the spark plugs. So, to avoid this problem, an accelerator pump is used. It regulates the exact amount of fuel required for normal engine operation, even when the gas is pressed hard.

The accelerator pump more often becomes clogged with sediment than breaks down, and then repairs are not needed, but simply cleaning is enough. But, if this is not the case, but there is still a breakdown, then the pump needs to be repaired urgently, otherwise operation of the engine of the VAZ 2109 car will be impossible, and you are guaranteed to have pedal failures.

The first symptoms that the pump is faulty is that when you press the pedal, the speed does not increase steadily, but floats. This is due to a shortage, or vice versa, an excess of fuel. The spark plugs do not have time to burn out all the gasoline, and they are simply flooded, so the car jerks while driving. Also, the pedal may fail when pressed.

Repair for such a breakdown is as follows:

We take out the sprayer; Shake it. If there is a characteristic knocking sound of the ball inside, then the sprayer is working, if not, then this will be the reason why the pedal failed; The pump has a rather heavy structure with parts. A large number of holes and channels increases the chance that the pump will clog, and pedal failure will be inevitable. If the holes are clogged, then repairs are not needed. You just need to buy carburetor cleaning fluid and use it to blow out the channels.

Pay attention to the operation of the fuel pump

You should also check the operation of the fuel accelerator in the carburetor using a fuel pump. In particular, gasoline in the form of small streams from the spray nozzles must appear almost at the first moment when the specified throttle valve begins to open.

If streams of gasoline appear with a delay, then a “failure” of engine operation will be felt in the future at the very beginning of the car’s movement.

To solve this problem, it is worth inspecting the lever, the eccentric with which the accelerator is driven, and, of course, its diaphragm. Often the sprayer itself becomes clogged.

EPHH VAZ 2109

Almost all VAZ models with a carburetor power system are equipped with a forced idle economizer. EPHH VAZ 2109 is an electronic device designed for: a) To save vehicle fuel; b) To prevent the supply of fuel to the engine when it is turned off; c) To cut off the fuel supply to the engine through the idle system during engine braking.

Economizer

The economizer consists of the following parts: 1) Economizer module 2) Solenoid valve 3) Throttle valve limit switch. Remember, if at least one of these nodes is faulty, the EPHH will not work. Let's look at how this block reduces the fuel consumption of a VAZ car. The block has input and output circuits. The economizer input circuits are the throttle valve limit switch and the wire connected to the switch. What information do they provide? a) The throttle limit switch tells you whether the gas pedal is pressed or not. If the gas pedal is not pressed, the limit switch is shorted to ground. As soon as the gas pedal is pressed by the driver, this contact disappears.

Throttle limit switch

b) Pulses to the ignition coil are read through a wire connected between the economizer and the switch. This is done so that he knows the actual engine speed of the car.

The economizer reads pulses onto the coil from the commutator

There is only one output circuit of the block - this is the carburetor idle speed solenoid valve. The economizer turns this valve on or off.

Idle speed solenoid valve VAZ 2109

The principle of fuel saving is based on closing the idle fuel jet of the carburetor at high engine speeds of the nine. If the gas pedal is not pressed, the throttle limit switch is shorted to ground, and the engine speed is less than 2100 rpm, then the economizer opens the idle speed solenoid valve.

Operating principle of the economizer

As soon as the driver presses the gas pedal, the limit switch will open, but the valve will still remain open. The valve will close only if the gas pedal is pressed and the engine speed exceeds 2100 rpm. The valve remains closed until the engine speed drops below 1900 rpm. This is the whole principle of operation of the VAZ 2109 economizer, but there is one point that you need to know: if the car is coasting with the gear engaged and the gas pedal released, the idle speed solenoid valve will not turn on, even at speeds less than 1900 rpm. The economizer monitors the closed position of the throttle valve and if the engine speed is abnormally high (higher than 800-1000 rpm at idle), it recognizes the vehicle's coasting motion. Fuel savings from using EPHH are about 5% of engine consumption. As a rule, if the economizer on a car is faulty, the following problems arise: - The engine stalls at idle - The engine stalls when coasting - Engine detonation when the ignition is turned off. Checking the correct operation of the economizer is done as follows: checking the inclusion of the idle speed solenoid valve in various engine operating modes. You can control the switching on either using a voltmeter or by ear (a click is heard when the valve is switched on or off). 1) Checking the basic operating mode of the economizer. We start the engine and gradually increase the engine speed. When crossing 2100 rpm, a click should occur - the valve turns off. We increase the speed to 4000 rpm, the idle speed solenoid valve should remain closed. Then we gradually lower the speed; when the speed drops below 1900 rpm, a click should occur - the valve turns on. 2) Checking the engine braking mode. We remove the chip from the throttle position limit switch and set it to ground, thereby deceiving the economizer by telling it that the gas pedal is always released. We start the engine and raise the speed to more than 4000 rpm, then gradually reduce it. When the 1900 rpm threshold is crossed, the valve should not turn on. A limit switch closed to ground and speeds above idle activate the economizer engine braking mode and it should not turn on the solenoid valve. 3) Checking the fuel cutoff when the ignition is turned off. With the car warmed up to 90 degrees, turn off the ignition. The engine should stop immediately without shaking or vibrating. Dieseling, detonation, glow ignition, vibration when switching off - all this is the same thing. And the reason for this negative phenomenon is that the idle speed solenoid valve does not close the idle fuel jet and fuel continues to flow into the hot engine. A malfunction of both the idle speed solenoid valve and the economizer itself most often leads to the fact that the car either constantly or in some situations stalls at idle. The forced idle economizer system of the ninth Zhiguli model is not very reliable; car owners often disable it. This increases fuel consumption slightly, but eliminates problems with the economizer and solenoid valve. To disable the EPHH, it is necessary to connect the wire going to the idle air solenoid valve to contact B of the ignition coil.

Ignition coil VAZ 2109

When you turn the ignition on, voltage will be applied to the coil, and this voltage will open the idle air solenoid valve. The valve will remain open until the ignition is turned off.

Decommissioning of the VAZ 2109 economizer

The ignition was turned off, the valve closed, the engine stalled.

Sources:

https://luxvaz.ru/vaz-2109/346-blok-upravleniya-elektromagnitnym-klapanom-karbyuratora.html https://mashinapro.ru/1220-klapan-2109.html https://tuningtaza.ru/%D0 %BF%D1%80%D0%BE%D0%B2%D0%B5%D1%80%D0%BA%D0%B0-%D0%B1%D0%BB%D0%BE%D0%BA%D0% B0-%D1%83%D0%BF%D1%80%D0%B0%D0%B2%D0%BB%D0%B5%D0%BD%D0%B8%D1%8F-%D1%8D%D0% BB%D0%B5%D0%BA%D1%82%D1%80%D0%BE%D0%BC%D0%B0%D0%B3%D0%BD%D0%B8%D1%82%D0%BD% D1%8B%D0%BC-%D0%BA%D0%BB%D0%B0%D0%BF%D0%B0%D0%BD%D0%BE%D0%BC-%D0%BA%D0%B0% D1%80%D0%B1%D1%8E%D1%80%D0%B0%D1%82%D0%BE%D1%80%D0%B0-%D0%AD%D0%9F%D0%A5%D0 %A5-%D0%B0%D0%B2%D1%82%D0%BE%D0%BC%D0%BE%D0%B1%D0%B8%D0%BB%D0%B8-%D0%B2%D0 %B0%D0%B7-2108-%D0%B2%D0%B0%D0%B7-2109-%D0%B2%D0%B0%D0%B7-21099.html https://www.vazzz.ru/ ephh-vaz-2109-karbyurator-shema-podklyucheniya/ https://vaz2109.net/electrooborudovanie/ephh-vaz-2109.html

Troubleshooting the unit

Upon completion of diagnostic operations on the VAZ 2107 engine, other breakdowns that may have similar manifestations should be excluded. The econometer works by changing the pressure in the carburetor channels; damage to its tube can lead to air leaks. A modern injector electronic control system eliminates electro-pneumatic devices that are less reliable.

An accurate determination of the cause of the EPHH malfunction is only possible if the unit is dismantled and completely disassembled. The economizer is removed from the carburetor in the following order:

- Using a “10” wrench, unscrew the 3 nuts holding the filter cover and lift it up along the studs.

- Unscrew two Phillips-head screws that secure the pneumatic block with the membrane and valve. The control tube is removed from the fitting of the device.

- The device is removed from the socket and carefully inspected for damage and carbon deposits on the valve or its seat.

The operation scheme of the carburetor, which was replaced by an injector, assumes a reaction to changes in pressure in the chamber with a decrease or increase in fuel supply. The economizer implements this feedback through a flexible membrane rigidly connected to the stem and valve

When checking this block, special attention should be paid to this node

There are repair kits for sale for Solex carburetors that were previously installed on the VAZ 2107. The forced idle unit, if it does not work, can be repaired using parts from such a kit. Installation of the unit in its intended place must be accompanied by a leak test. The last thing to connect before installing the air filter is the econometer located on the control panel. The position of the arrow in the green sector indicates acceptable fuel consumption.

Question. My car (VAZ-21044i 2000 (1700i engine, GM controller 21214-1411010/10 (EFI))) has an instrument panel from a VAZ-2107 that has an ECONOMIZER. As far as I know, it instantly indicates the fuel economy mode when driving (in response to the gas pedal). On my car, when starting the engine and driving, it is constantly in the red zone (arrow on the left) and there is no response to the gas pedal. As the engine warms up and drives (20 minutes), the needle gradually drops into the green zone (arrow in the center); when driving for about 1 hour, it comes closer to the edge of the green zone. At the warranty service station they told me that it would not work because... The sensor hose is connected not at the inlet (as on a VAZ-2107 car), but at the outlet to a tee near the adsorber. Should the economizer work on my car? If YES, then how to work. If it should work like on the VAZ-2107, then tell me how to fix this problem? Car enthusiast Konstantin Vasilievich Sidko, Kiev.

Answer. Actually an "econometer". A device that measures the vacuum in the intake pipe is quite useless for you. With the disappearance of the carburetor, which operates under vacuum, and the advent of trip computers capable of showing instantaneous and hourly consumption in particular. Back in 1984, the econometer was considered uninformative by German carburetor eight testers. You can revive it, since it is there anyway, as follows: Either in the hose from the tee you mentioned to the combination, or in the fitting of the combination there is a clogged damping nozzle. It is needed so that the needle does not twitch due to the cyclic operation of the pistons. Blow air under low pressure or pierce this jet with copper wire. It may contain debris, oil, condensate, fuel. Yakovlev Alexander Anatolyevich. Engine Design Department, Fuel Equipment and Toxicity Department

Owners of injection sevens will not find this material useful, unlike owners of Lada cars with a carburetor engine. After all, it was the carburetor models of the sevens that were equipped from the factory with such a device as the EPHH system of the VAZ 2107. If by the name of the economizer it is difficult to even imagine what it is, then by deciphering the EPHH - forced idle economizer, it becomes a little clearer what we are talking about.